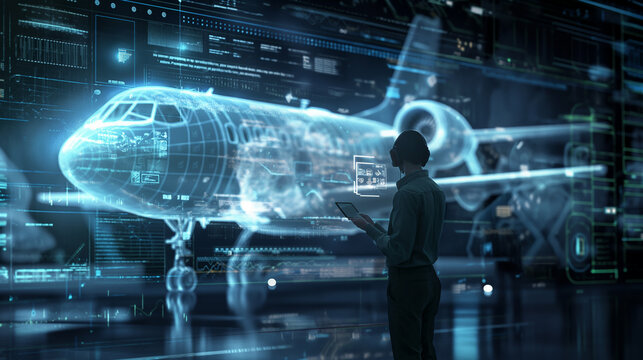

The concept of digital twins is revolutionizing various industries, and its impact on aerospace electronics is no exception. As we delve into the world of digital twins in aerospace electronics, it becomes apparent how this innovative technology is reshaping the landscape of aviation. By creating a virtual replica of physical systems, digital twins enable engineers to simulate, predict, and optimize performance without the need for physical prototypes. This advancement is particularly significant in the realm of aerospace, where precision and reliability are paramount.

Understanding Digital Twins

A digital twin is a virtual representation of a physical object or system. It uses real-time data and advanced algorithms to simulate the behavior and performance of its physical counterpart. This digital model helps in monitoring, diagnosing, and predicting potential issues, thereby enhancing decision-making processes. In the context of aerospace electronics, digital twins offer a transformative approach to managing complex systems and ensuring their optimal performance.

Applications in Aerospace Electronics

The application of digital twins in aerospace electronics spans several critical areas. From aircraft design and manufacturing to maintenance and operations, digital twins provide valuable insights that drive efficiency and innovation. For instance, in aircraft design, engineers can use digital twins to test various configurations and materials before actual production. This not only reduces costs but also accelerates the development cycle.

Enhancing Aircraft Design

In the design phase, digital twins allow engineers to explore different design scenarios and assess their impact on performance. By simulating various conditions and stress tests, potential issues can be identified and addressed early in the development process. This proactive approach minimizes risks and enhances the overall safety and reliability of the aircraft.

Streamlining Manufacturing Processes

During manufacturing, digital twins facilitate precise monitoring and control of the production line. By analyzing real-time data, manufacturers can optimize processes, reduce waste, and improve quality. This results in more efficient production and a higher standard of aerospace electronics.

Improving Maintenance and Operations

One of the most significant advantages of digital twins in aerospace electronics is their role in maintenance and operations. By continuously monitoring the condition of aircraft components, digital twins enable predictive maintenance, reducing downtime and extending the lifespan of critical systems.

Predictive Maintenance

Predictive maintenance relies on data collected from digital twins to forecast when a component is likely to fail. This allows maintenance teams to perform necessary repairs or replacements before a failure occurs, preventing costly delays and ensuring the safety of passengers and crew.

Enhancing Operational Efficiency

In addition to maintenance, digital twins enhance operational efficiency by providing real-time insights into aircraft performance. This information can be used to optimize flight paths, fuel consumption, and other operational parameters, leading to more sustainable and cost-effective operations.

Challenges and Future Prospects

While the benefits of digital twins in aerospace electronics are undeniable, there are also challenges to overcome. These include data security, integration with existing systems, and the need for skilled personnel to manage and interpret complex data sets. As technology continues to evolve, the potential for digital twins in aerospace electronics is vast. With ongoing advancements in artificial intelligence and machine learning, digital twins are poised to become even more sophisticated and integral to the aerospace industry.

Addressing Data Security Concerns

Data security is a critical concern when implementing digital twins. Ensuring that sensitive information is protected from cyber threats is paramount. Implementing robust security measures and protocols will be essential to safeguard data integrity and maintain trust in digital twin technology.

Integration with Existing Systems

Integrating digital twins with existing aerospace systems requires careful planning and execution. Ensuring compatibility and seamless communication between digital twins and traditional systems is crucial for maximizing their potential.

The Role of Skilled Personnel

The successful implementation of digital twins in aerospace electronics relies on having skilled personnel who can manage and interpret the data generated by digital twins. Training and development programs will be essential to equip engineers and technicians with the necessary skills to harness the full potential of this technology.

Conclusion

The advent of digital twins in aerospace electronics marks a new era of innovation and efficiency in aviation. By providing a virtual mirror of physical systems, digital twins enable a deeper understanding of complex aerospace electronics and offer a proactive approach to design, manufacturing, maintenance, and operations. As the aerospace industry continues to embrace this transformative technology, the possibilities for improving safety, performance, and sustainability are limitless.

FAQs

What are digital twins?

Digital twins are virtual representations of physical objects or systems, using real-time data to simulate their behavior and performance.

How do digital twins benefit aerospace electronics?

In aerospace electronics, digital twins enhance design, manufacturing, maintenance, and operations by providing valuable insights and enabling predictive maintenance.

What challenges do digital twins face?

Challenges include data security, integration with existing systems, and the need for skilled personnel to manage and interpret complex data sets.

For more information on aerospace electronics, you can visit Aerospace Electronics or explore our related articles on Development Cycle and Navigation Systems.