The consumer gadget manufacturing turnkey process is a streamlined approach that simplifies the production of electronic devices. This process is particularly beneficial for exporters and importers who seek efficiency and quality in their manufacturing ventures. Understanding this process is crucial for businesses aiming to thrive in the competitive consumer electronics market.

What is a Turnkey Process?

A turnkey process refers to a complete solution where a single provider manages all aspects of production, from design and prototyping to final manufacturing and delivery. This method is favored for its simplicity and efficiency, enabling companies to focus on marketing and distribution.

Benefits of a Turnkey Process in Gadget Manufacturing

One of the main advantages of the turnkey process is the reduction of time and complexity. By outsourcing all stages of production to a single provider, companies can minimize delays and ensure consistent quality. Learn how turnkey ensures consistent product quality.

Cost-Efficiency

By consolidating various production stages, the turnkey approach often results in cost savings. It eliminates the need for multiple contracts and negotiations, leading to more predictable expenses.

Quality Control

With a single entity managing the entire process, quality control becomes more streamlined. This ensures a consistent product that meets the required standards and specifications.

Steps Involved in the Turnkey Process

The turnkey process involves several critical steps, each essential to producing high-quality consumer gadgets.

Design and Prototyping

The initial phase involves designing the product and creating prototypes. This step is crucial for refining the design and ensuring that it meets customer needs.

Component Sourcing

Once the design is finalized, the next step is sourcing the necessary components. A turnkey provider typically has established relationships with suppliers, ensuring timely and cost-effective procurement.

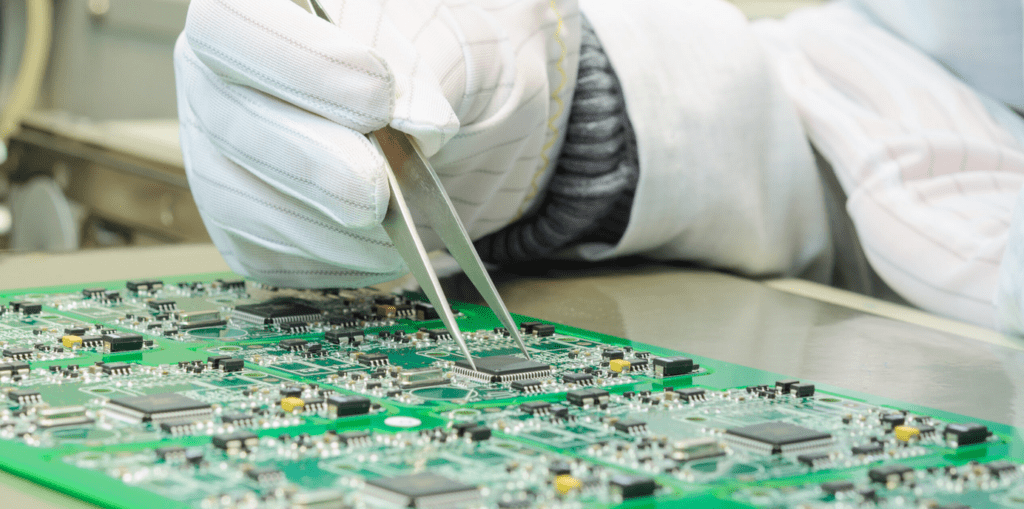

Manufacturing and Assembly

The actual manufacturing and assembly phase involves producing the gadget according to the specified design. This stage is critical for ensuring that the product is built to precise specifications.

Testing and Quality Assurance

Before the product is finalized, it undergoes rigorous testing and quality assurance checks. Learn more about automated inspection in turnkey electronics.

Why Exporters and Importers Should Consider Turnkey

The turnkey process is ideal for exporters and importers due to its simplicity and reliability. This approach allows them to focus on their core business activities, such as sales and distribution.

Streamlined Logistics

By consolidating the production process, logistics become simpler and more efficient, reducing the risk of delays and complications.

Scalability

The turnkey process is scalable, allowing businesses to adjust production volumes according to market demands without significant changes to their operations.

Challenges and Considerations

Despite its benefits, the turnkey process also presents some challenges. Businesses must choose their providers carefully to ensure they meet the required standards and capabilities.

Choosing the Right Provider

It is crucial to select a provider with a proven track record and the necessary expertise in consumer gadget manufacturing. Consider factors such as experience, reputation, and the range of services offered.

Communication and Collaboration

Effective communication and collaboration between the business and the turnkey provider are essential for a successful partnership. Regular updates and feedback help ensure that the project stays on track.

Conclusion

The consumer gadget manufacturing turnkey process offers a comprehensive solution for businesses in the electronics industry. By streamlining production and consolidating various stages, it provides an efficient and cost-effective way to bring products to market. For exporters and importers, this approach is particularly advantageous, allowing them to focus on their core activities while ensuring high-quality products. To dive deeper into the benefits of turnkey solutions, check out this external resource.

FAQs

What is the main advantage of a turnkey process?

The primary advantage is its ability to simplify and streamline the production process, reducing time and costs associated with managing multiple suppliers and contracts.

How does a turnkey process improve quality?

By consolidating all stages of production under one provider, the turnkey process allows for more consistent quality control and adherence to standards.

Are there risks in using a turnkey provider?

While the turnkey process offers many benefits, businesses must carefully select a provider with the right expertise and a proven track record to mitigate risks.