Building and testing electronic circuits requires a reliable set of circuit prototyping materials. Whether you are a hobbyist, student, or professional engineer, having the right tools and components on hand can make the difference between a smooth prototyping process and a frustrating experience. This guide covers the fundamental supplies needed for hands-on electronics development, from breadboards and jumper wires to more advanced prototyping boards and consumables. Understanding the role of each material will help you select the best options for your next project.

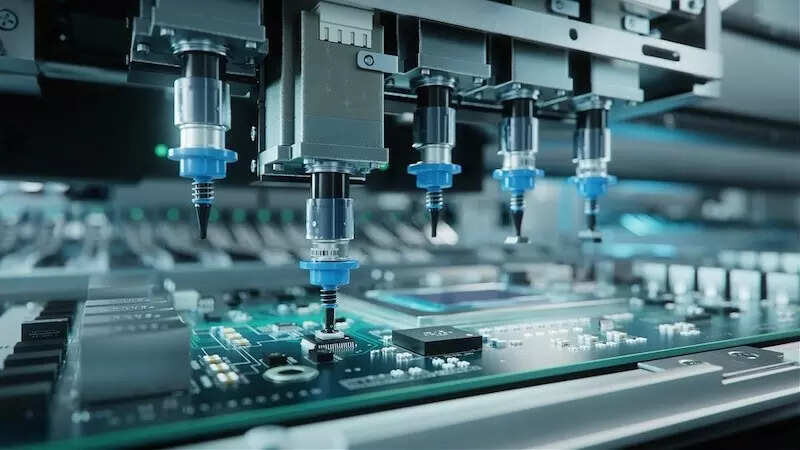

For those interested in the broader context of electronics production, you may also want to explore electronics manufacturing steps to see how prototyping fits into the overall process.

Core Supplies for Building Electronic Prototypes

The foundation of any prototyping setup is a collection of versatile and reusable materials. These allow you to assemble, modify, and test circuits efficiently before committing to a final design. Below are the most common items found on every electronics workbench.

Breadboards and Their Importance in Prototyping

Breadboards are indispensable for quickly assembling and testing circuits without soldering. They feature a grid of interconnected holes that accept component leads and jumper wires, making it easy to rearrange connections as you refine your design. Breadboards come in various sizes, from compact mini boards to large panels suitable for complex projects.

Using breadboards allows for rapid iteration, which is especially valuable during the early stages of development. They are ideal for testing new ideas, troubleshooting, and educational purposes. For more permanent solutions, other types of prototyping boards are available.

Jumper Wires and Connectors

Jumper wires are flexible, insulated wires with solid tips or connectors at each end. They are used to make temporary electrical connections on breadboards, microcontroller headers, and other prototyping boards. Jumper wires come in male-to-male, male-to-female, and female-to-female configurations, supporting a wide range of applications.

In addition to standard jumper wires, having a selection of header pins, sockets, and terminal blocks can help you connect modules, sensors, and other components quickly and securely.

Prototyping Boards: From Breadboards to Stripboards

While breadboards are great for initial testing, other types of prototyping boards offer more durability and flexibility for semi-permanent builds. These boards allow for soldering, which provides stronger electrical connections and better mechanical stability.

Stripboards and Perfboards

Stripboards (also known as Veroboard) feature parallel copper strips running along the board, which can be cut to create custom circuit layouts. Perfboards have a grid of isolated holes, each surrounded by a copper pad, allowing for point-to-point wiring. Both are suitable for soldering components and are commonly used for building prototypes that need to withstand handling or transport.

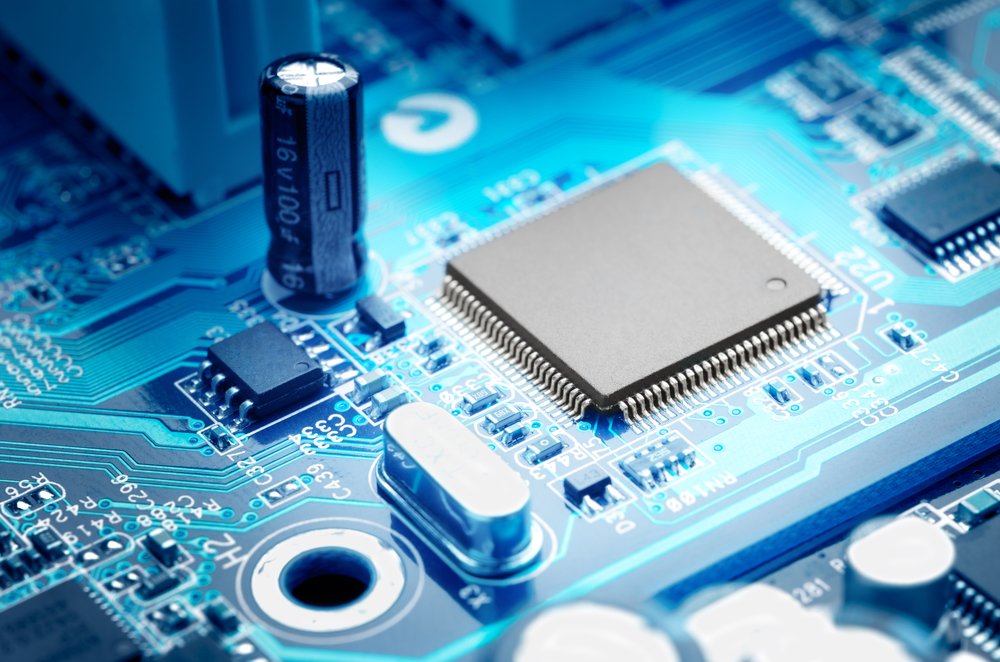

When choosing between stripboard and perfboard, consider the complexity of your circuit and whether you prefer to create bus lines or individual connections. For more details on the materials used in circuit boards, see circuit board materials explained.

Prototyping Shields and Custom PCBs

For microcontroller projects, prototyping shields are available that fit directly onto development boards like Arduino or Raspberry Pi. These shields provide a convenient area for adding custom circuits and are often compatible with breadboard layouts.

As your design matures, you may want to transition to a custom printed circuit board (PCB). Designing a PCB allows for a compact, robust, and professional-looking final product. If you are new to this process, you can learn more about how to design a PCB from scratch.

Essential Electronic Components for Prototyping

No prototyping setup is complete without a well-organized assortment of electronic components. Stocking a variety of basic parts ensures you can experiment and troubleshoot without delay.

- Resistors: Used to limit current and divide voltages.

- Capacitors: Store and release electrical energy, filter signals, and stabilize power supplies.

- Diodes: Allow current to flow in one direction, protecting circuits from reverse voltage.

- Transistors: Act as switches or amplifiers in electronic circuits.

- Integrated Circuits (ICs): Perform complex functions, from logic gates to microcontrollers.

- LEDs: Indicate circuit status or provide visual feedback.

- Switches and Buttons: Enable user input and control.

- Potentiometers: Allow for adjustable resistance, useful in tuning and calibration.

Organizing these components in labeled drawers or boxes can save time and reduce frustration during the prototyping process.

Tools and Consumables for Circuit Assembly

In addition to boards and components, several tools and consumables are vital for assembling and testing circuits. Here are the most frequently used items:

- Soldering iron and solder: Required for making permanent connections on stripboards, perfboards, and custom PCBs.

- Wire cutters and strippers: Essential for preparing wires and component leads.

- Multimeter: Used to measure voltage, current, resistance, and continuity.

- Power supply: Provides adjustable voltage and current for powering prototypes safely.

- Desoldering pump or braid: Helps remove solder during rework or troubleshooting.

- Tweezers: Useful for handling small components.

- Heat shrink tubing and electrical tape: For insulating and protecting connections.

Having these tools readily available ensures that you can assemble, modify, and repair circuits efficiently.

Best Practices for Organizing Your Prototyping Workspace

A well-organized workspace improves productivity and safety. Arrange your circuit prototyping materials so that frequently used items are within easy reach. Use storage bins, component organizers, and cable management solutions to keep your bench tidy.

Label all containers and drawers clearly. Regularly inventory your supplies to avoid running out of critical parts mid-project. Keeping your workspace clean also reduces the risk of accidental shorts or component loss.

Further Learning and Industry Insights

As you gain experience, you may want to explore more advanced topics such as surface-mount technology, automated assembly, or the transition from prototype to mass production. For a deeper dive into the manufacturing side of electronics, check out this comprehensive overview of the electronics manufacturing process.

Understanding how prototyping fits into the larger workflow will help you design more robust and manufacturable products in the future.

Frequently Asked Questions

What are the most important materials for circuit prototyping?

The most essential materials include breadboards, jumper wires, a variety of electronic components (such as resistors, capacitors, and ICs), prototyping boards like stripboard or perfboard, and basic tools like a soldering iron and multimeter.

How do breadboards differ from stripboards and perfboards?

Breadboards allow for solderless assembly and easy reconfiguration, making them ideal for early-stage testing. Stripboards and perfboards require soldering and are better suited for semi-permanent or more robust prototypes.

Why is it important to organize circuit prototyping supplies?

Proper organization saves time, reduces errors, and helps maintain a safe and efficient workspace. It also ensures that you have the necessary parts available when you need them, minimizing project delays.