Understanding circuit design rules is essential for anyone involved in electronics, whether you’re designing a simple prototype or working on complex printed circuit boards (PCBs) for mass production. These guidelines ensure that electronic circuits are reliable, manufacturable, and function as intended. In this article, we’ll break down the core principles behind these rules, discuss why they matter, and provide practical advice for applying them to your own projects.

By following established standards, designers can avoid common pitfalls such as signal interference, manufacturing defects, and unexpected failures. If you’re new to PCB development or want to improve your existing workflow, getting familiar with these guidelines is a crucial step. For those interested in related topics, you might also want to learn about what are test points and how they impact circuit validation and troubleshooting.

What Are Circuit Design Rules?

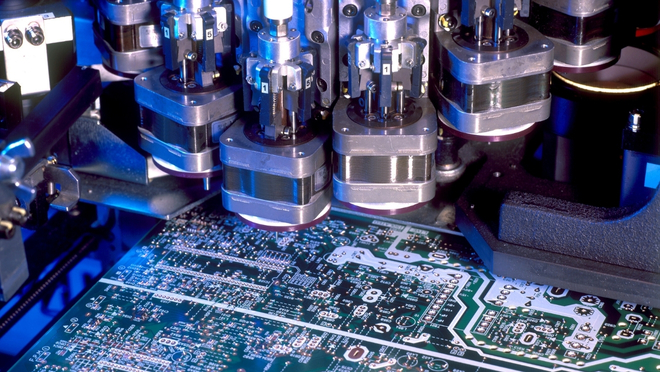

At their core, circuit design rules are a set of constraints and recommendations that guide the layout and interconnection of electronic components on a PCB. These rules cover everything from the minimum spacing between traces to the maximum current a copper path can safely carry. By adhering to these requirements, designers ensure that their circuits are both functional and manufacturable.

The main objectives of these guidelines are to prevent electrical shorts, minimize electromagnetic interference, and guarantee that the final product can be reliably produced using standard manufacturing processes. These standards are enforced by design software, which checks your layout for violations before you send it for fabrication.

Key Categories of PCB Design Constraints

When working with PCBs, several categories of rules must be considered. Each plays a vital role in ensuring that the board performs as expected and can be produced without issues.

- Clearance and Spacing: Defines the minimum distance between traces, pads, and vias to prevent electrical shorts and arcing.

- Trace Width: Specifies the minimum and maximum width of copper traces, which affects current-carrying capacity and thermal management.

- Annular Ring: Refers to the width of the copper ring around a via or hole, ensuring strong electrical and mechanical connections.

- Component Placement: Involves guidelines for positioning components to optimize signal integrity, manufacturability, and ease of assembly.

- Power and Ground Planes: Ensures robust power delivery and noise reduction by providing dedicated layers or areas for power and ground connections.

- Thermal Relief: Addresses how heat is managed, particularly around components that dissipate significant power.

Why Following Circuit Board Design Rules Matters

Adhering to these constraints is not just about passing automated checks in your design software. It directly impacts the reliability, performance, and cost-effectiveness of your electronic products. Violating these standards can lead to a range of problems, including:

- Short circuits or open circuits due to insufficient spacing or improper trace width

- Signal integrity issues, such as crosstalk and electromagnetic interference

- Manufacturing defects, like incomplete solder joints or misaligned components

- Reduced lifespan of the product due to thermal stress or mechanical failure

For a deeper dive into the basics of PCB construction and why these rules are enforced, consider reviewing this comprehensive introduction to PCB fundamentals.

Applying Circuit Design Guidelines in Practice

Most modern PCB design tools allow you to set and customize these rules according to your project’s requirements and the capabilities of your chosen manufacturer. Here’s how you can put these principles into action:

- Consult Manufacturer Specifications: Always check the fabrication capabilities of your PCB supplier, including minimum trace width, spacing, and hole sizes.

- Set Up Design Rules in Software: Enter these values into your CAD tool before starting your layout. This ensures that any violations are flagged immediately.

- Run Design Rule Checks (DRC): Use the built-in DRC feature to scan your design for any issues. Address all errors and warnings before submitting your files for production.

- Review for Manufacturability: Beyond automated checks, manually inspect your layout for potential assembly or testing issues. For example, consider how test points are placed for post-production inspection.

If you’re interested in the specifics of how certain PCB features are created, such as via formation or copper plating, you can read more about how vias are made in PCBs and the copper plating process explained on our blog.

Common Mistakes and How to Avoid Them

Even experienced designers can overlook certain aspects of PCB layout. Here are some frequent errors and tips to prevent them:

- Ignoring Manufacturer Limits: Using trace widths or spacing below the minimum supported by your fabricator can result in defective boards.

- Poor Component Placement: Crowding components or placing them too close to the board edge can complicate assembly and increase the risk of damage.

- Overlooking Thermal Management: Failing to provide adequate heat dissipation can lead to premature component failure.

- Insufficient Test Points: Not including enough accessible points for testing can make troubleshooting and quality control much harder. For more on this, see our guide on electronics inspection methods.

Best Practices for Reliable Circuit Layouts

To ensure your designs meet industry standards and function reliably, keep these best practices in mind:

- Document All Requirements: Clearly specify all design constraints in your project documentation.

- Communicate with Your Manufacturer: Share your design files and ask for feedback on manufacturability before finalizing your layout.

- Stay Updated: Regularly review updates to industry standards and your manufacturer’s capabilities.

- Use Automated Tools: Leverage DRC and other automated checks, but always supplement with manual review.

- Plan for Testing: Integrate test points and consider how your board will be inspected and debugged during production.

FAQ: Circuit Design Rule Essentials

What happens if I violate PCB layout constraints?

Violating these guidelines can result in manufacturing defects, unreliable operation, and even complete board failure. Common issues include short circuits, signal interference, and components that cannot be assembled or tested properly.

How do I know which design rules to use for my project?

Start by consulting your PCB manufacturer’s specifications. Most suppliers provide detailed documentation on their minimum and maximum supported values for trace width, spacing, and other parameters. Your design software may also offer default profiles for common manufacturing processes.

Can I customize circuit board rules for special applications?

Yes, many advanced projects—such as high-frequency or high-power circuits—require custom constraints. Work closely with your manufacturer and use your CAD tool’s rule editor to tailor these settings to your specific needs.

Conclusion

Mastering the principles behind circuit design rules is fundamental for producing reliable, efficient, and manufacturable electronic products. By understanding and applying these guidelines, you can minimize risks, streamline production, and ensure your circuits perform as intended. For further reading on related PCB processes, explore our articles on how stencil printing works and other manufacturing techniques.