Understanding the composition of printed circuit boards (PCBs) is essential for anyone involved in electronics design, manufacturing, or repair. The choice of materials directly impacts electrical performance, durability, and production costs. In this guide, we’ll break down the essential materials used in PCB construction, their properties, and how they influence the final product. Whether you’re a hobbyist, engineer, or simply curious about electronics, gaining insight into these materials will help you make informed decisions for your projects.

For a deeper dive into how these materials interact during manufacturing, you might find the PCB etching process explained particularly useful. This resource covers the chemical and mechanical steps that shape the copper layers on a board, providing context for the material choices discussed here.

The Foundation: Substrate and Core Materials

At the heart of every PCB lies the substrate, which provides mechanical support and electrical insulation. The most common base material is FR-4, a composite made from woven fiberglass cloth and epoxy resin. FR-4 is favored for its excellent strength-to-weight ratio, flame resistance, and stable electrical properties across a range of temperatures.

- FR-4 (Flame Retardant 4): The industry standard for most general-purpose PCBs. It offers a good balance of cost, durability, and performance.

- CEM-1 and CEM-3: Cheaper alternatives to FR-4, made from cellulose paper reinforced with epoxy. These are typically used in low-cost consumer electronics.

- Polyimide: Used in flexible and high-temperature applications, polyimide substrates withstand greater thermal stress but come at a higher price.

- Ceramic: For specialized, high-frequency, or high-power circuits, ceramic bases provide superior heat dissipation and electrical insulation.

The choice of substrate not only affects the board’s mechanical strength but also determines its electrical insulation, thermal resistance, and suitability for various environments. For more on how these layers are structured, see our article on understanding PCB layers.

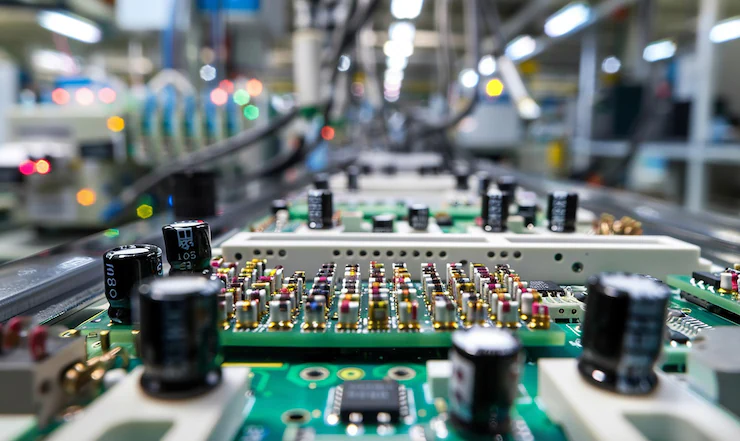

Copper Foil: The Conductor of Choice

The next critical layer is the copper foil, which forms the conductive traces and pads. Copper is universally used due to its high electrical conductivity, ductility, and affordability. The thickness of copper layers is measured in ounces per square foot, with 1 oz/ft² (about 35 microns) being standard for most applications.

- Standard Copper: Used for signal and power traces in most consumer and industrial electronics.

- Heavy Copper: Boards with thicker copper layers (2 oz/ft² or more) are chosen for high-current or high-power circuits, such as power supplies and motor controllers.

- Electro-deposited (ED) vs. Rolled Annealed (RA): ED copper is common for rigid boards, while RA copper is more flexible and used in flexible PCBs.

The copper is bonded to the substrate using heat and adhesives, then patterned through processes like etching. If you’re interested in the details of this process, our resource on the PCB etching process explained provides a step-by-step overview.

Protective Layers: Solder Mask and Silkscreen

To safeguard the copper traces and prevent accidental short circuits, a layer of solder mask is applied. This is the colored coating—often green, but also available in red, blue, black, and other colors—that covers most of the board’s surface except for exposed pads.

- Solder Mask: Made from epoxy or liquid photoimageable (LPI) polymers, this layer insulates the copper and defines areas where soldering is allowed.

- Silkscreen: The white (or sometimes yellow) markings on a PCB are applied using epoxy ink. Silkscreen labels components, test points, and other important information for assembly and troubleshooting.

The quality of these protective layers affects not only the board’s reliability but also its ease of assembly and maintenance. For a closer look at assembly processes, see our guide on how SMT assembly works.

Surface Finishes and Plating Options

Exposed copper pads are prone to oxidation, which can hinder soldering and electrical contact. To address this, various surface finishes are applied:

- HASL (Hot Air Solder Leveling): A layer of solder is applied and leveled with hot air. It’s cost-effective but not ideal for fine-pitch components.

- ENIG (Electroless Nickel Immersion Gold): A thin layer of gold over nickel provides excellent solderability and is preferred for high-reliability and fine-pitch boards.

- OSP (Organic Solderability Preservative): An organic coating that protects copper during storage and assembly, suitable for lead-free processes.

- Immersion Silver/Tin: Alternatives that offer good solderability and are RoHS-compliant.

The choice of finish depends on the application, component density, and environmental requirements. Each type has trade-offs in terms of cost, shelf life, and compatibility with assembly processes.

Specialized PCB Materials for Advanced Applications

As electronic devices become more complex, the demand for specialized materials grows. High-frequency, high-speed, and high-power applications often require substrates with unique properties:

- Rogers Materials: Engineered for RF and microwave circuits, these laminates offer low dielectric loss and stable performance at high frequencies.

- Aluminum and Metal-Core PCBs: Used for LED lighting and power electronics, metal-core boards provide superior heat dissipation.

- Flexible and Rigid-Flex Materials: Polyimide and other flexible substrates enable circuits to bend and fold, essential for wearable and compact devices.

Selecting the right advanced material is crucial for ensuring signal integrity, thermal management, and long-term reliability in demanding environments.

How Material Choices Affect Performance and Cost

The selection of PCB materials is a balancing act between performance, manufacturability, and budget. Here are some key considerations:

- Thermal Stability: High-temperature environments require substrates like polyimide or ceramic to prevent warping and failure.

- Electrical Properties: Signal speed and integrity depend on the dielectric constant and loss tangent of the substrate.

- Mechanical Strength: Applications subject to vibration or mechanical stress benefit from robust materials like FR-4 or metal cores.

- Cost: While advanced materials offer superior performance, they increase manufacturing expenses. For many consumer products, standard FR-4 strikes the best balance.

For more practical guidance on assembly and joining techniques, our article on soldering techniques explained covers the best practices for working with different PCB finishes and materials.

Further Learning and Resources

If you want to expand your understanding of electronics and PCB technology, the comprehensive electronics tutorials website offers a wealth of diagrams, explanations, and practical examples. Whether you’re troubleshooting, designing, or assembling boards, staying informed about material science will help you achieve better results.

For a comparison of assembly methods and how they relate to board materials, see our article on the difference between SMT and through hole assembly.

Frequently Asked Questions

What is the most common material used for PCB substrates?

The vast majority of PCBs use FR-4 as the base material. This fiberglass-reinforced epoxy laminate offers a reliable mix of mechanical strength, electrical insulation, and cost-effectiveness, making it suitable for most consumer and industrial electronics.

How does the choice of copper thickness affect a circuit board?

Thicker copper layers allow a PCB to handle higher currents and improve heat dissipation. However, they also increase manufacturing costs and can complicate the etching process. Standard boards use 1 oz/ft² copper, while power electronics may require 2 oz/ft² or more.

Why are different surface finishes used on PCBs?

Surface finishes like HASL, ENIG, and OSP protect exposed copper from oxidation and ensure good solderability during assembly. The choice depends on factors such as component density, environmental requirements, and the need for lead-free compliance.