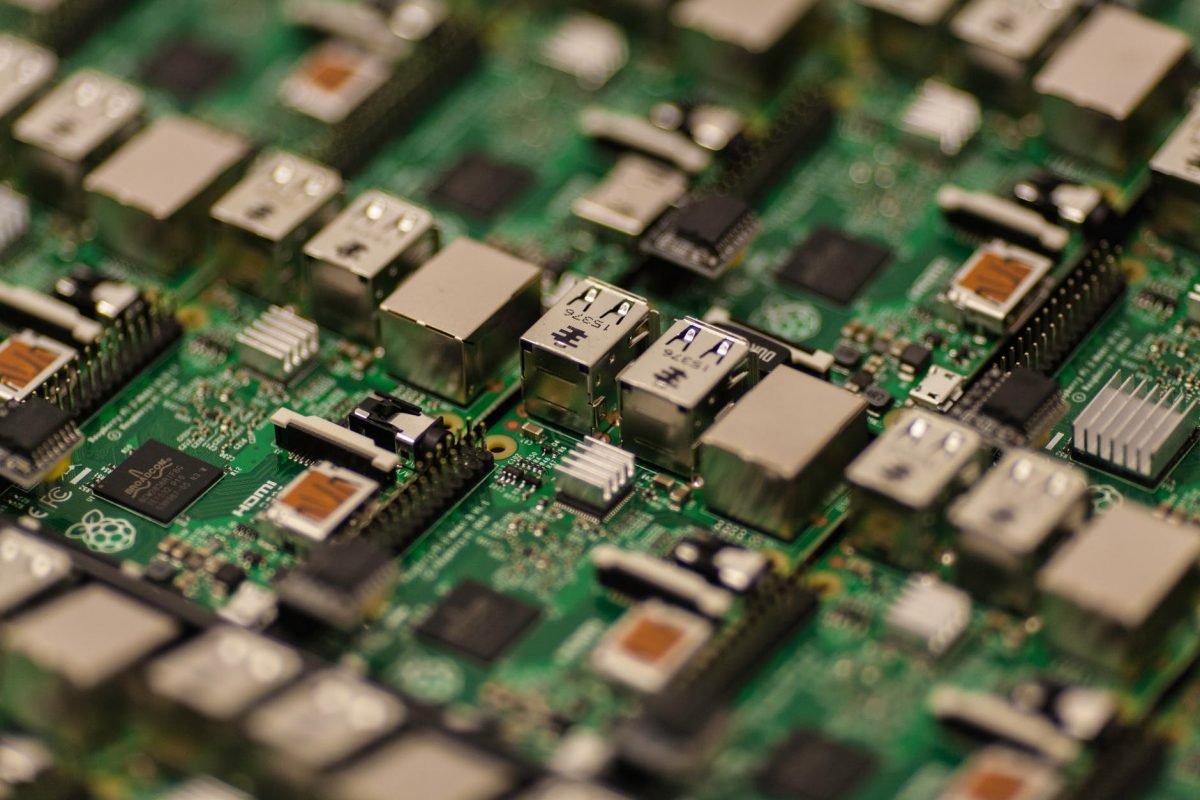

In recent years, the integration of AI driven quality control in turnkey electronics has revolutionized the manufacturing industry. This innovation is not just a trend but a necessity that plays a vital role in ensuring high-quality standards in electronic products. The demand for sophisticated and efficient quality control methods has increased significantly, especially among exporters and importers who rely on consistent product quality.

The deployment of AI technology in quality control processes is transforming the traditional methods used in electronics prototyping and mass production. This article delves into the various aspects of this technology and its impact on the electronics manufacturing sector.

The Importance of Quality Control in Electronics

Quality control is a critical component of the electronics manufacturing process. It ensures that every product meets the required standards and specifications before reaching the market. In the past, quality control heavily relied on manual inspection, which was not only time-consuming but also prone to human error. With the advent of AI driven quality control, manufacturers can now achieve higher accuracy and efficiency.

Challenges in Traditional Quality Control

Traditional quality control methods face several challenges, including the difficulty of detecting subtle defects and the high costs associated with manual inspections. These challenges often result in inconsistencies in product quality, which can lead to customer dissatisfaction and increased returns.

Benefits of AI in Quality Control

The introduction of AI in quality control processes has addressed many of these challenges. AI systems can analyze vast amounts of data quickly and accurately, identifying defects that might be missed by human inspectors. This not only improves product quality but also reduces the time and cost associated with quality control.

How AI Driven Quality Control Works

AI driven quality control utilizes advanced algorithms and machine learning techniques to monitor and analyze production processes. These systems are capable of learning from past data and continuously improving their performance over time.

Data Analysis and Machine Learning

Machine learning algorithms play a crucial role in AI driven quality control. They analyze data from various stages of the production process to identify patterns and anomalies. This allows manufacturers to detect defects early and make necessary adjustments to improve product quality.

Real-Time Monitoring and Feedback

AI systems provide real-time monitoring and feedback, enabling manufacturers to respond quickly to any issues that arise during production. This real-time capability is essential for maintaining high-quality standards and minimizing production downtime.

Impact on Turnkey Electronics

The impact of AI driven quality control on turnkey electronics is profound. It has enabled manufacturers to produce high-quality products more efficiently, meeting the ever-growing demands of the market. This is particularly important for companies involved in turnkey procurement, where maintaining consistent quality is crucial.

Improved Product Quality and Consistency

AI driven quality control ensures that every product meets the desired quality standards. This consistency is vital for building consumer trust and maintaining a strong reputation in the market.

Cost Efficiency and Productivity

By reducing the need for manual inspections and minimizing defects, AI driven quality control enhances productivity and cost efficiency. This allows manufacturers to allocate resources more effectively and focus on other critical aspects of production.

Future Trends in AI Driven Quality Control

The future of AI driven quality control in turnkey electronics looks promising. As technology continues to evolve, we can expect further advancements that will enhance its capabilities and applications in the manufacturing sector.

Integration with IoT and Industry 4.0

The integration of AI with the Internet of Things (IoT) and Industry 4.0 technologies will further enhance quality control processes. This will enable manufacturers to create smart factories that are more efficient and responsive to market demands.

Enhanced Predictive Maintenance

AI systems will also play a significant role in predictive maintenance, allowing manufacturers to identify potential issues before they become major problems. This proactive approach will reduce downtime and improve overall production efficiency.

Conclusion

In conclusion, AI driven quality control is transforming the electronics manufacturing industry. Its ability to improve product quality, enhance efficiency, and reduce costs makes it an indispensable tool for manufacturers. As the technology continues to evolve, its impact on turnkey electronics will only grow stronger, paving the way for a more innovative and efficient future.

For more insights on electronics manufacturing, check out this detailed guide on turnkey electronic manufacturing.

FAQs

What is AI driven quality control?

AI driven quality control uses advanced algorithms and machine learning to enhance the quality assurance processes in manufacturing, ensuring products meet high standards.

How does AI benefit turnkey electronics?

AI benefits turnkey electronics by improving product quality, enhancing efficiency, and reducing the costs associated with manual inspections and defect management.

What is the future of AI in quality control?

The future of AI in quality control is promising, with advancements in IoT and predictive maintenance expected to further enhance its capabilities and applications in manufacturing.