The world of electronics manufacturing is constantly evolving, driven by rapid advances in technology, increasing product complexity, and the demand for higher reliability. Navigating the electronics fabrication challenges faced by manufacturers and engineers is essential for delivering quality products that meet market expectations. From sourcing reliable components to ensuring precise assembly, each stage presents unique obstacles that require careful planning and expertise.

Understanding these hurdles is not just important for engineers and production managers, but also for anyone involved in the supply chain, quality assurance, or product design. By addressing common pain points early, companies can reduce costs, minimize delays, and improve end-product performance. For those interested in the finer details of PCB manufacturing, learning about what are test points can provide valuable insights into testing and quality control strategies.

Key Obstacles in Modern Electronics Manufacturing

As electronic devices become more compact and powerful, the processes used to fabricate them must adapt. This evolution brings a host of new electronics fabrication challenges that can impact everything from production timelines to product reliability.

- Component Miniaturization: The trend toward smaller, more densely packed components increases the risk of assembly errors and makes inspection more difficult.

- Supply Chain Disruptions: Global shortages and logistical bottlenecks can delay critical parts, leading to production slowdowns or redesigns.

- Complex PCB Designs: Advanced circuit boards require precise manufacturing techniques and introduce new variables, such as multilayer alignment and via integrity.

- Quality Assurance: Ensuring consistent quality across high-volume runs is increasingly challenging as products become more intricate.

Material Selection and Sourcing Difficulties

Choosing the right materials is foundational to successful electronics fabrication. However, the selection process is complicated by factors such as cost, availability, and compatibility with advanced manufacturing processes. For example, high-frequency applications may require specialized substrates, while lead-free regulations can limit solder choices.

Sourcing high-quality materials is further complicated by fluctuating global markets and the risk of counterfeit components. Establishing strong supplier relationships and implementing rigorous incoming inspection protocols are vital steps in overcoming these sourcing hurdles.

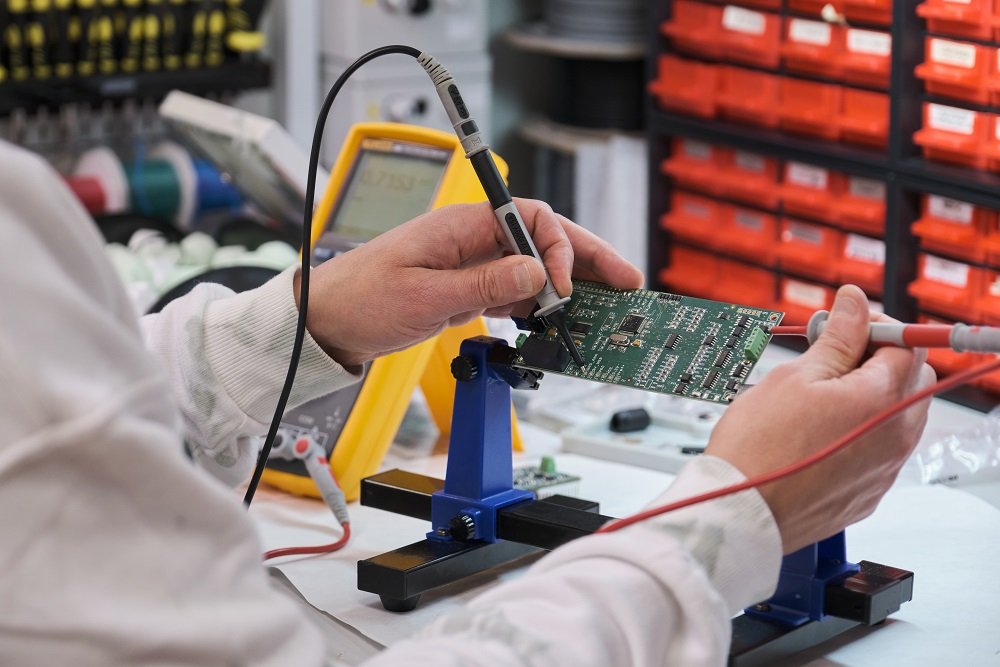

Precision Assembly and Process Control

Assembling modern electronic devices demands a high degree of accuracy. The rise of surface-mount technology (SMT) and fine-pitch components means that even minor misalignments can result in defective products. Manufacturers must invest in advanced placement equipment and real-time process monitoring to maintain tight tolerances.

Process control extends to every stage of production, from solder paste application to reflow soldering and final inspection. For a deeper look at specific assembly steps, understanding how stencil printing works in PCB assembly can shed light on the importance of precise material deposition.

Testing, Inspection, and Quality Assurance

Ensuring product reliability requires robust testing and inspection protocols. Automated optical inspection (AOI), X-ray analysis, and functional testing are commonly used to detect defects such as solder bridges, missing components, or electrical shorts. However, as boards become more complex, traditional inspection methods may not catch every issue.

Integrating advanced inspection techniques and continuous feedback loops into the manufacturing process can help identify trends and prevent recurring problems. For those interested in comprehensive evaluation strategies, exploring electronics inspection methods can provide practical guidance.

Addressing Traceability and Regulatory Compliance

Traceability is a critical aspect of modern electronics manufacturing, especially for industries such as automotive, aerospace, and medical devices. Being able to track every component and process step helps manufacturers quickly identify and address issues, ensuring compliance with industry standards and regulations.

Implementing traceability systems can be complex, requiring integration with supply chain management and production tracking tools. However, the benefits—such as improved recall management and enhanced customer confidence—often outweigh the initial investment.

Overcoming Process-Specific Issues

Each fabrication process introduces its own set of challenges. For instance, the copper plating process explained highlights the importance of uniform deposition and defect prevention in PCB manufacturing. Similarly, creating reliable vias requires precise drilling and plating techniques, as discussed in resources about how vias are made in PCBs.

Staying up to date with the latest process improvements and industry best practices is essential for minimizing defects and maximizing yield.

Staying Ahead of Industry Trends

The electronics industry is characterized by rapid innovation. Manufacturers must adapt to new materials, evolving design standards, and emerging technologies such as flexible electronics and additive manufacturing. Keeping pace with these changes requires ongoing investment in research, equipment, and workforce training.

For a comprehensive overview of semiconductor manufacturing and its complexities, refer to this ultimate guide to semiconductor fabrication processes.

Best Practices for Managing Electronics Fabrication Challenges

Successfully navigating the obstacles of electronics manufacturing involves a combination of proactive planning, strong supplier relationships, and continuous process improvement. Here are some practical strategies:

- Design for Manufacturability (DFM): Collaborate closely with manufacturing partners during the design phase to minimize production risks and optimize layouts.

- Supplier Audits: Regularly evaluate suppliers for quality, reliability, and compliance to reduce the risk of counterfeit or substandard parts.

- Process Automation: Invest in automation and real-time monitoring to improve consistency and reduce human error.

- Employee Training: Provide ongoing training to ensure staff are familiar with the latest equipment and industry standards.

- Continuous Improvement: Use data-driven feedback loops to identify bottlenecks and implement corrective actions quickly.

FAQ: Common Questions About Electronics Fabrication

What are the most frequent causes of defects in electronics manufacturing?

Common sources of defects include poor soldering, incorrect component placement, contamination, and inadequate process control. Addressing these issues requires robust inspection, precise assembly techniques, and strict adherence to quality standards.

How can manufacturers ensure component traceability?

Implementing barcode or RFID tracking systems, maintaining detailed records, and working with reputable suppliers all contribute to effective traceability. This is especially important for industries with strict regulatory requirements.

Why is process control so important in electronics fabrication?

Tight process control ensures consistent product quality, reduces scrap rates, and minimizes the risk of defects. Automated monitoring and feedback systems help manufacturers quickly detect and correct deviations from established parameters.

How do supply chain disruptions impact electronics manufacturing?

Delays or shortages in critical components can halt production, increase costs, and force design changes. Building strong supplier relationships and maintaining buffer inventories can help mitigate these risks.

What role does testing play in ensuring product reliability?

Comprehensive testing—such as AOI, X-ray, and functional tests—detects defects early and ensures that only fully functional products reach customers. This reduces warranty claims and enhances brand reputation.