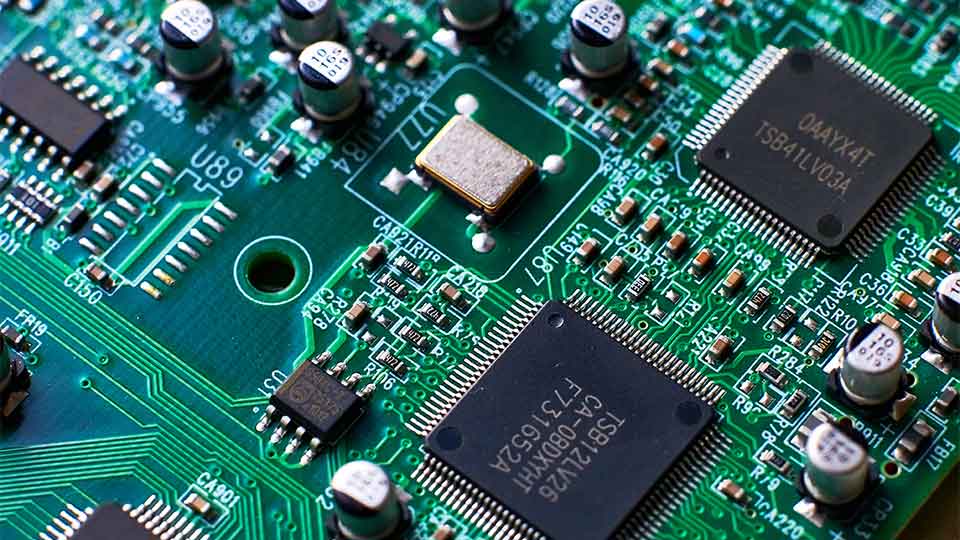

In our increasingly connected world, understanding electromagnetic interference explained is crucial for anyone involved with electronics, manufacturing, or even everyday technology use. This phenomenon, often abbreviated as EMI, can cause disruptions in electronic devices, leading to performance issues, data loss, or even complete system failures. Whether you are designing printed circuit boards, working in electronics assembly, or simply curious about how electronic systems interact, learning about EMI helps ensure reliability and safety.

Before diving into the causes, effects, and mitigation strategies for EMI, it’s helpful to connect this topic to related areas in electronics. For example, knowing what are test points on a PCB can be essential for diagnosing and addressing interference issues during the testing phase.

What Is Electromagnetic Interference?

At its core, electromagnetic interference refers to the unwanted disturbance that affects an electrical circuit due to electromagnetic radiation emitted from an external source. These disturbances can degrade the performance of the circuit or even prevent it from functioning. EMI can be caused by both natural sources, such as lightning or solar flares, and man-made sources, including motors, wireless transmitters, and switching power supplies.

EMI is a significant concern in environments where multiple electronic devices operate in close proximity. For instance, in manufacturing plants or data centers, the presence of various machines and communication equipment increases the risk of interference. Understanding how EMI works is the first step toward minimizing its impact.

Types and Sources of EMI

There are two primary types of electromagnetic interference: conducted EMI and radiated EMI. Conducted EMI travels along electrical conductors, such as wires or PCB traces, while radiated EMI propagates through the air as electromagnetic waves. Both types can disrupt sensitive electronic equipment, but they require different mitigation strategies.

- Natural sources: Lightning, static electricity, and cosmic noise.

- Man-made sources: Electric motors, radio transmitters, switching power supplies, and even everyday household appliances.

In the context of electronics manufacturing, EMI can originate from high-frequency circuits, poorly shielded cables, or inadequate grounding. For more details about how components are fabricated and how EMI can be introduced during production, you can explore this comprehensive guide to semiconductor fabrication.

How EMI Affects Electronic Devices

The effects of electromagnetic interference can range from minor annoyances, like audio static, to severe malfunctions in critical systems. In consumer electronics, EMI might cause flickering screens or dropped wireless connections. In industrial or medical settings, interference can compromise data integrity or disrupt life-saving equipment.

Some common symptoms of EMI include:

- Unexpected resets or shutdowns

- Corrupted data or communication errors

- Reduced signal quality in audio or video devices

- False triggering of sensors or alarms

These issues highlight the importance of robust design and testing methods. For instance, understanding electronics inspection methods can help identify and address EMI-related problems during the production process.

Diagnosing and Measuring Electromagnetic Interference

Detecting EMI requires specialized tools and techniques. Engineers often use spectrum analyzers, oscilloscopes, and EMI receivers to identify the frequency, amplitude, and source of interference. Testing is typically performed in shielded environments, such as anechoic chambers, to minimize external noise and obtain accurate measurements.

Key steps in diagnosing EMI include:

- Identifying symptoms and affected devices

- Measuring interference levels across different frequencies

- Tracing the source using near-field probes or current clamps

- Implementing and verifying mitigation strategies

Regular testing is essential in industries where reliability is critical, such as aerospace, automotive, and medical device manufacturing.

Mitigating EMI in Electronic Systems

Reducing electromagnetic interference involves a combination of design best practices, shielding, and filtering. Here are some proven methods:

- Shielding: Enclosing sensitive circuits or cables in conductive materials to block external electromagnetic fields.

- Filtering: Installing filters on power and signal lines to suppress unwanted frequencies.

- Grounding: Ensuring proper grounding of equipment to provide a path for stray currents and reduce noise.

- PCB layout optimization: Minimizing loop areas, separating analog and digital grounds, and careful trace routing.

- Cable management: Using twisted pair or coaxial cables and keeping signal lines away from noise sources.

For those involved in PCB manufacturing, understanding processes like the copper plating process explained can help ensure robust designs that are less susceptible to EMI.

Best Practices for Preventing Interference

Preventing EMI starts at the design stage. Here are some best practices to consider:

- Use multilayer PCBs to separate power and ground planes.

- Keep high-speed signal traces short and well-shielded.

- Isolate noisy components from sensitive analog circuits.

- Implement proper decoupling and bypass capacitors.

- Test early and often during the development cycle.

Additionally, understanding how vias are made in PCBs can help engineers design more effective signal paths and minimize interference risks.

Electromagnetic Interference in Modern Manufacturing

As electronics become more compact and powerful, the risk of EMI increases. High-density circuit boards, wireless communication modules, and rapid switching devices all contribute to a more challenging electromagnetic environment. Manufacturers must stay updated on the latest standards and testing protocols to ensure compliance and product reliability.

For example, in PCB assembly, knowing how stencil printing works can help reduce the introduction of EMI during solder paste application and component placement.

FAQ

What are the most common sources of EMI in homes and offices?

Common sources include wireless routers, microwave ovens, fluorescent lighting, cordless phones, and even power adapters. These devices can emit electromagnetic noise that affects nearby electronics, especially if shielding or grounding is inadequate.

How can I tell if my device is experiencing electromagnetic interference?

Signs of EMI include unexpected resets, data corruption, audio or video distortion, and intermittent connectivity problems. If these issues occur when new devices are introduced or when equipment is moved, EMI could be the cause.

What steps can I take to reduce EMI in my electronics projects?

Use shielded cables, ensure proper grounding, add filtering components, and keep sensitive circuits away from noisy components. Testing your design in different environments can also help identify and address potential interference issues.