As electronic devices become more compact and powerful, managing heat effectively is a critical challenge for engineers and manufacturers. Thermal management in electronics refers to the set of strategies and technologies used to control temperatures within electronic systems, ensuring reliability, safety, and optimal performance. Without proper heat dissipation, components can degrade, malfunction, or even fail prematurely, leading to increased costs and potential safety risks.

Whether designing consumer gadgets, industrial machinery, or automotive systems, understanding how to keep electronic components within safe temperature limits is essential. This guide explores the fundamentals of heat control in electronic assemblies, practical methods for dissipating heat, and best practices for integrating thermal solutions into your designs.

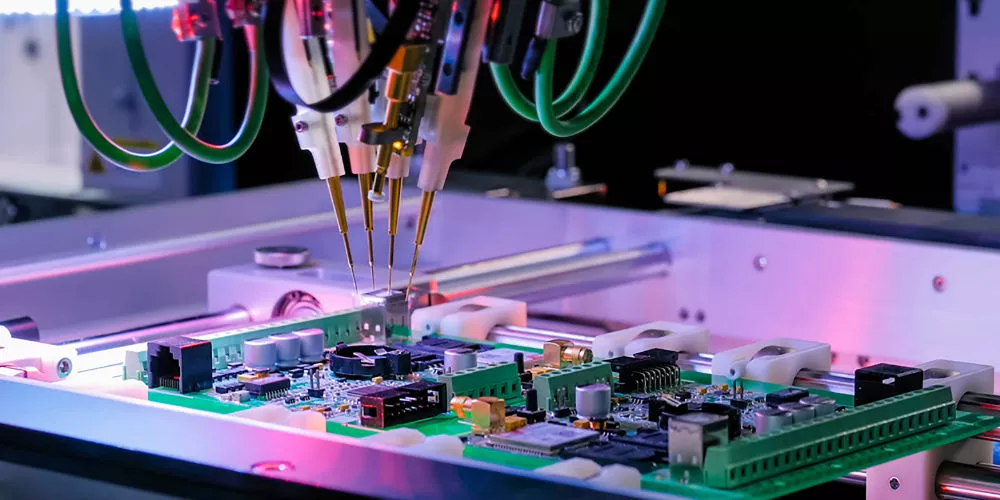

For those interested in the finer details of circuit board construction, understanding what are test points can further enhance your approach to both testing and thermal considerations in modern PCB design.

Why Effective Heat Control Matters in Electronic Devices

Excessive heat is one of the leading causes of electronic component failure. As circuits operate, they generate heat through electrical resistance and power consumption. If this heat is not efficiently removed, it can cause:

- Reduced lifespan of semiconductors and passive components

- Performance degradation due to thermal throttling or drift

- Physical damage such as warping, melting, or solder joint failure

- Safety hazards including fire risks in extreme cases

In high-density assemblies, such as smartphones, servers, or automotive control units, the challenge is even greater. The need for robust thermal management solutions grows as devices shrink and power densities increase.

Key Principles of Thermal Management in Electronic Assemblies

Managing heat in electronic systems involves a combination of design strategies and material choices. The main principles include:

- Minimizing heat generation: Selecting efficient components and optimizing circuit layouts can reduce the amount of heat produced.

- Efficient heat transfer: Using materials and structures that conduct heat away from sensitive components helps maintain safe operating temperatures.

- Effective heat dissipation: Incorporating features like heat sinks, fans, and thermal interface materials allows heat to escape into the surrounding environment.

By applying these principles, engineers can design products that operate reliably under a wide range of conditions.

Common Methods for Managing Heat in Electronics

There are several widely used techniques for controlling temperature in electronic systems. Each method has its own advantages and is chosen based on the application’s requirements.

Passive Cooling Techniques

- Heat sinks: These metal components attach to heat-generating parts, increasing the surface area for heat transfer. Aluminum and copper are common choices due to their high thermal conductivity.

- Thermal vias and planes: In printed circuit boards, thermal vias connect layers to spread heat, while copper planes act as heat spreaders. For more on PCB construction, see the copper plating process explained.

- Thermal interface materials (TIMs): These materials, such as thermal pads or pastes, fill microscopic gaps between surfaces to improve heat transfer.

- Enclosure design: Properly designed cases and ventilation slots can enhance natural convection, allowing heat to escape passively.

Active Cooling Solutions

- Fans and blowers: Moving air across components increases heat removal, especially in high-power devices like servers or gaming consoles.

- Liquid cooling: Used in demanding applications, liquid coolants absorb and transport heat away from hot spots more efficiently than air.

- Thermoelectric coolers: These devices use the Peltier effect to pump heat from one side to another, offering precise temperature control for sensitive electronics.

Design Considerations for Efficient Heat Dissipation

Integrating thermal management strategies into the design phase is far more effective than retrofitting solutions later. Here are some important considerations:

- Component placement: High-power parts should be spaced apart and located near heat sinks or airflow paths.

- PCB layout: Use wide copper traces and planes to spread heat. Incorporate thermal vias to connect hot spots to larger cooling areas.

- Material selection: Choose substrates and enclosures with good thermal conductivity. Aluminum housings, for example, can act as both structure and heat sink.

- Simulation and testing: Use thermal simulation tools during design, and validate with real-world testing. For more on quality assurance, review electronics inspection methods.

Emerging Trends in Heat Control for Electronics

As technology evolves, so do the methods for managing heat in electronic assemblies. Some notable trends include:

- Advanced materials: Graphene, phase-change materials, and nanocomposites offer higher thermal conductivity and improved performance.

- Miniaturized cooling solutions: Micro heat pipes and vapor chambers are being integrated into compact devices.

- Smart thermal management: Sensors and control systems dynamically adjust cooling based on real-time temperature data.

- Sustainable design: Energy-efficient cooling methods reduce environmental impact and operating costs.

For a broader look at how electronics are manufactured and assembled, the electronics manufacturing process overview provides valuable context on integrating heat management into production workflows.

Best Practices for Implementing Thermal Solutions

To ensure reliable operation and long product life, follow these best practices when addressing heat in electronic devices:

- Start early: Address heat issues during initial design, not as an afterthought.

- Balance performance and cost: Choose solutions that meet thermal requirements without unnecessary complexity or expense.

- Test under real conditions: Simulate worst-case scenarios and validate with physical prototypes.

- Document and monitor: Keep records of thermal analysis and monitor field performance to catch issues early.

Frequently Asked Questions

What are the most common causes of overheating in electronic devices?

Overheating often results from inadequate heat dissipation, poor airflow, high ambient temperatures, or excessive power consumption. Faulty components and improper assembly can also contribute to thermal issues.

How can I improve heat management in a compact electronic design?

Use high-conductivity materials, optimize PCB layout with thermal vias and planes, and consider advanced cooling solutions like micro heat pipes. Ensuring good airflow and minimizing power density also help control temperatures in small devices.

Is passive or active cooling better for electronics?

Passive cooling is simpler, quieter, and often sufficient for low- to moderate-power devices. Active cooling, such as fans or liquid systems, is necessary for high-power or densely packed electronics where passive methods alone cannot maintain safe temperatures.

How does PCB design affect heat dissipation?

PCB design plays a significant role in heat management. Wide copper areas, thermal vias, and strategic component placement help spread and remove heat efficiently. For details on manufacturing techniques, see how vias are made in PCBs.