Building modern electronic devices requires a precise set of tools and equipment. Whether you are assembling printed circuit boards, prototyping circuits, or performing repairs, having the right instruments can make a significant difference in efficiency, safety, and the quality of your work. This guide explores the essential electronics fabrication tools list for both beginners and professionals, outlining their uses and why they matter in the fabrication process.

Understanding the purpose and application of each tool helps streamline workflows and ensures reliable results. For those interested in deeper aspects of PCB assembly, you may also find value in learning about how stencil printing works in PCB assembly, which is a critical step for surface mount technology.

Core Instruments for Circuit Assembly

The foundation of any electronics fabrication tools list starts with basic hand tools and measurement devices. These are indispensable for assembling, soldering, and troubleshooting electronic circuits.

- Soldering Iron and Soldering Station: Used for joining components to PCBs. Adjustable temperature stations offer better control, reducing the risk of damaging sensitive parts.

- Wire Cutters and Strippers: Essential for preparing wires and component leads. Precision cutters ensure clean cuts, while strippers help remove insulation without damaging conductors.

- Tweezers: Fine-tipped tweezers are necessary for handling small surface-mount components and placing them accurately on the board.

- Multimeter: A digital or analog multimeter allows for measuring voltage, current, resistance, and continuity, which is vital for circuit testing and troubleshooting.

- PCB Holder or Third Hand Tool: These devices stabilize the board during soldering, freeing up your hands for more precise work.

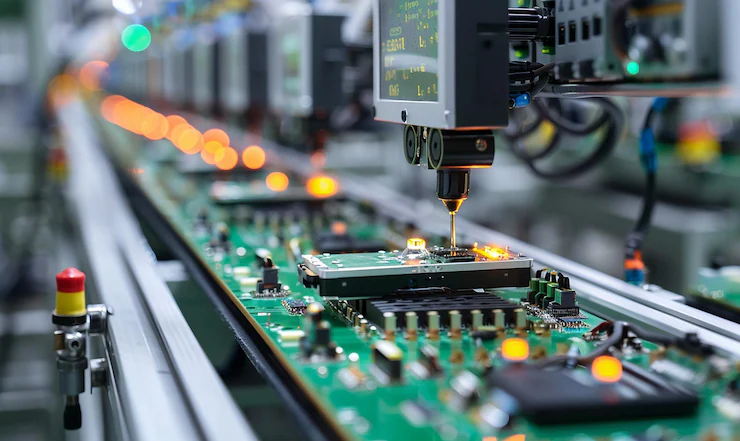

Advanced Equipment for PCB Fabrication

As projects become more complex, additional tools are required for tasks such as prototyping, surface mount assembly, and inspection. Expanding your electronics fabrication toolkit with these items can improve the quality and reliability of your builds.

- Hot Air Rework Station: Used for soldering and desoldering surface-mount components, especially useful for ICs and multi-pin packages.

- Oscilloscope: Allows visualization of electrical signals, making it easier to diagnose timing issues and signal integrity problems.

- Function Generator: Produces test signals for circuit analysis and development.

- Power Supply: Adjustable bench power supplies provide stable voltage and current for powering prototypes and testing circuits safely.

- Magnifying Lamp or Microscope: Critical for inspecting fine-pitch solder joints and verifying component placement, especially on densely populated boards.

Essential Tools for PCB Prototyping and Repair

Prototyping and repair work often require specialized instruments. Including these in your electronics fabrication tools list ensures you are prepared for modifications, debugging, and maintenance.

- Desoldering Pump and Wick: These tools help remove excess solder or replace faulty components without damaging the PCB pads.

- PCB Prototyping Boards (Breadboards and Perfboards): Useful for temporary circuit assembly and testing before committing to a final design.

- Heat Gun: Used for heat-shrink tubing and reflow soldering of certain components.

- IC Extractor and Inserter: Safe removal and insertion of integrated circuits, minimizing the risk of bent pins or static damage.

- Cleaning Brushes and Isopropyl Alcohol: For cleaning flux residues and ensuring reliable electrical connections.

Safety and Inspection Tools for Electronics Work

Safety and quality control are as important as assembly. Incorporating inspection and protective equipment into your electronics fabrication toolkit helps prevent accidents and ensures finished products meet required standards.

- ESD Mat and Wrist Strap: Protects sensitive components from electrostatic discharge during handling and assembly.

- Fume Extractor: Removes harmful soldering fumes, improving air quality and protecting your health.

- Safety Glasses: Shields eyes from solder splashes, clipped leads, and accidental tool slips.

- Inspection Mirrors: Allows viewing of solder joints and components in hard-to-reach areas of the board.

- Test Points and Probes: Facilitate easy measurement and diagnostics during testing and troubleshooting. For more details, see what are test points in PCB design.

Reference Guides and Learning Resources

Staying updated with best practices and new technologies is essential in electronics fabrication. In addition to having the right tools, leveraging educational resources can enhance your skills and understanding of the fabrication process.

For a comprehensive overview of printed circuit board basics, including manufacturing techniques and material selection, refer to this detailed PCB basics tutorial.

If you are interested in specific fabrication steps, such as the copper plating process explained or electronics inspection methods, these guides provide valuable insights for both hobbyists and professionals.

Organizing and Maintaining Your Fabrication Tools

Proper organization and maintenance of your electronics fabrication tools can extend their lifespan and improve workflow. Consider the following tips:

- Store hand tools in a dedicated toolbox or on a pegboard for easy access.

- Clean soldering tips and replace consumables like solder and desoldering wick regularly.

- Calibrate measurement instruments, such as multimeters and oscilloscopes, to ensure accuracy.

- Label storage containers for small parts and components to prevent mix-ups.

- Keep safety equipment, like ESD straps and safety glasses, within reach at all times.

Frequently Asked Questions

What are the most important tools for beginners in electronics fabrication?

Beginners should start with a soldering iron, wire cutters, tweezers, a multimeter, and a breadboard. These basic instruments cover most assembly and prototyping needs and provide a solid foundation for learning more advanced techniques.

How do I choose the right soldering station for my projects?

Look for a soldering station with adjustable temperature control, interchangeable tips, and a comfortable grip. For surface-mount work, a station with a hot air rework feature can be especially useful.

Why is ESD protection critical in electronics assembly?

Electrostatic discharge can damage sensitive electronic components, leading to failures that may not be immediately apparent. Using ESD mats and wrist straps helps dissipate static charges safely, protecting your work and ensuring long-term reliability.

Where can I learn more about PCB manufacturing and assembly processes?

There are many online resources, including tutorials and articles. For a thorough introduction, the PCB basics tutorial covers essential concepts and practical tips.