Creating electronic circuits that are easy and cost-effective to manufacture is a crucial skill for engineers and product developers. When you prioritize design for manufacturability (DFM), you reduce production costs, minimize errors, and help ensure a smooth transition from prototype to mass production. This guide explores practical strategies, best practices, and common pitfalls to avoid when preparing your circuit designs for manufacturing at scale.

Whether you’re developing a new product or refining an existing one, understanding the principles behind manufacturable circuit layouts can save time, money, and headaches. Early attention to DFM not only benefits your bottom line but also improves product quality and reliability in the field.

For those new to printed circuit board (PCB) design, it’s helpful to understand related concepts such as what are test points, which play a vital role in inspection and troubleshooting during manufacturing.

Key Principles for Manufacturable Circuit Design

To ensure your circuits are ready for efficient production, it’s essential to follow certain foundational guidelines. These principles help streamline assembly, reduce rework, and improve overall yield.

- Simplicity: Keep layouts as straightforward as possible. Avoid unnecessary complexity in routing and component placement.

- Standardization: Use standard component packages and footprints to ensure availability and compatibility with automated assembly equipment.

- Clear Documentation: Provide complete and accurate documentation, including schematics, bills of materials (BOM), and assembly drawings.

- Design Rules Compliance: Adhere to the manufacturer’s design rules for trace widths, spacing, hole sizes, and other physical constraints.

- Testability: Incorporate features that facilitate inspection and testing, such as accessible test points and clear labeling.

Component Selection and Placement for Efficient Assembly

Choosing the right components and placing them thoughtfully on your PCB can have a significant impact on manufacturability. Here are some tips to optimize this process:

- Use Common Parts: Select widely available components to avoid sourcing delays and reduce costs.

- Group Similar Components: Place resistors, capacitors, and other similar parts together to simplify pick-and-place operations.

- Maintain Consistent Orientation: Align polarized components (like diodes and electrolytic capacitors) in the same direction to minimize assembly errors.

- Allow Adequate Spacing: Ensure there is enough space between components for soldering and inspection, especially for automated assembly.

- Minimize Crossovers: Reduce the number of trace crossovers and vias to simplify routing and improve reliability. For more on this, see the article on how vias are made in PCBs.

Optimizing PCB Layout for Manufacturability

The layout of your PCB is a critical factor in how easily and reliably it can be manufactured. Here are several layout considerations that directly affect DFM:

- Panelization: Design your boards to fit standard panel sizes, which maximizes material usage and reduces waste.

- Trace and Pad Sizing: Follow manufacturer guidelines for minimum trace widths and pad sizes to prevent defects during etching and soldering.

- Thermal Management: Place heat-generating components thoughtfully and provide adequate copper areas or thermal vias for heat dissipation.

- Silkscreen Clarity: Ensure all reference designators and polarity markings are clear and not obscured by pads or vias.

- Stackup Consistency: Maintain a consistent layer stackup to avoid warping and ensure predictable electrical performance.

For a deeper look at how copper is deposited and its impact on reliability, refer to copper plating process explained.

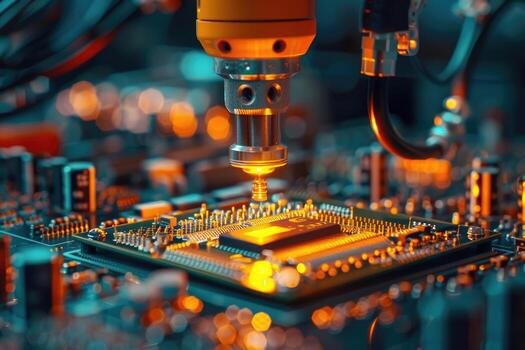

Designing for Automated Assembly and Inspection

Modern electronics manufacturing relies heavily on automation. To ensure your design is compatible with automated processes, consider the following:

- Surface Mount Technology (SMT): Favor SMT components over through-hole parts for faster and more reliable assembly.

- Stencil Printing Considerations: Design solder pads and mask openings to match stencil printing capabilities. For more, see how stencil printing works in PCB assembly.

- Inspection Accessibility: Place test points and connectors where automated optical inspection (AOI) and in-circuit testing (ICT) tools can easily access them. For an overview of inspection strategies, consult electronics inspection methods.

- Fiducial Marks: Include fiducials on the PCB for accurate alignment during pick-and-place and inspection processes.

Automated testing is a key part of the manufacturing process. For a comprehensive overview of component testing, check out this overview of test methods for electronic components.

Common Pitfalls and How to Avoid Them

Even experienced designers can fall into traps that complicate manufacturing. Here are some frequent mistakes and tips to prevent them:

- Ignoring Manufacturer Capabilities: Always consult with your PCB fabricator and assembler early in the design process to ensure your design matches their capabilities.

- Overlooking Tolerances: Specify realistic mechanical and electrical tolerances to avoid assembly issues and rework.

- Poor Documentation: Incomplete or ambiguous documentation can lead to costly mistakes during assembly.

- Neglecting Testability: Failing to provide adequate test points or clear labeling makes troubleshooting and quality control much harder.

- Underestimating Thermal Issues: Not planning for heat dissipation can result in product failures and reduced lifespan.

Frequently Asked Questions

What is the main goal of designing circuits for manufacturability?

The primary objective is to create circuit layouts that are easy, reliable, and cost-effective to produce at scale. This involves optimizing component selection, layout, and documentation to align with manufacturing processes and equipment.

How can I ensure my PCB design is easy to test during production?

Include accessible test points, clear reference designators, and consider the requirements of automated inspection tools. Early collaboration with your manufacturer can help identify the best strategies for testability.

Why is component standardization important in manufacturable designs?

Using standard, widely available components reduces sourcing delays, lowers costs, and ensures compatibility with automated assembly equipment. It also helps minimize the risk of obsolescence.

How do I choose the right manufacturer for my circuit boards?

Look for a manufacturer with experience in your application area, strong quality control processes, and clear communication. Sharing your design files early and seeking feedback can help ensure a smooth production process.