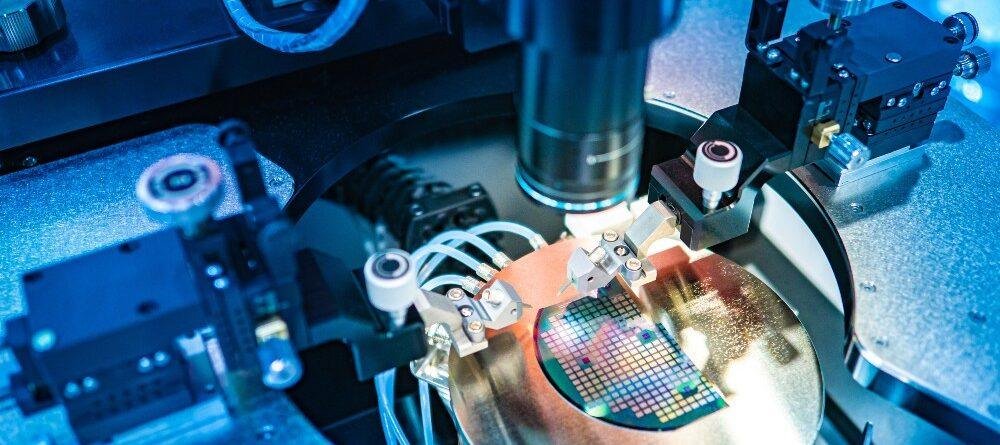

The process of assembling electronic devices is intricate, involving multiple steps that require precision and attention to detail. Even with advanced automation and strict quality controls, electronics assembly defects can still occur, impacting the reliability, performance, and safety of finished products. Understanding the most frequent issues, their causes, and how to identify them is crucial for anyone involved in manufacturing, quality assurance, or electronics design.

This guide offers a practical overview of typical problems encountered during printed circuit board (PCB) assembly and component mounting. By learning to recognize these issues early, manufacturers and engineers can reduce costly rework, improve yields, and deliver more dependable products to market. For those interested in the finer points of PCB testing, you may also want to explore what are test points and their role in quality assurance.

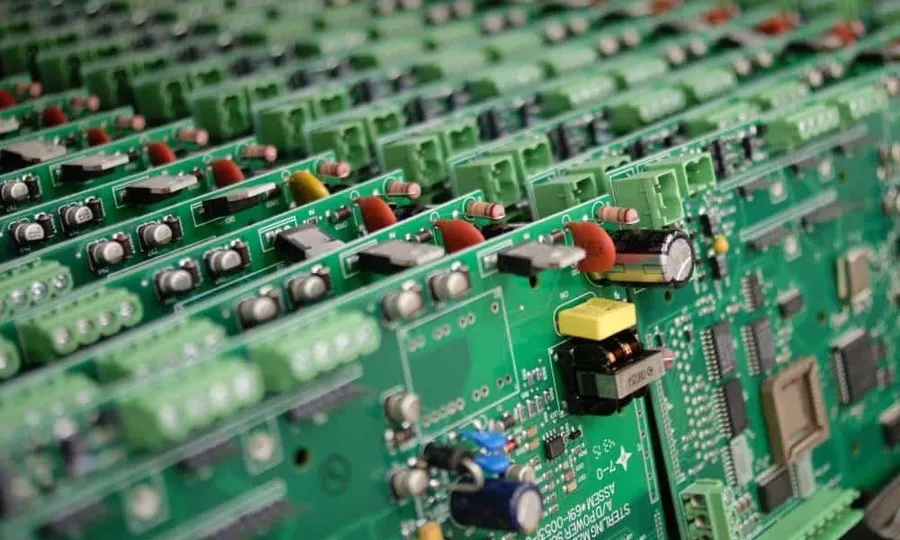

Understanding the Most Frequent Issues in PCB Assembly

During the assembly of electronic circuits, a variety of defects can arise. Some are visible to the naked eye, while others require specialized inspection techniques. The most common problems typically fall into several categories: soldering faults, component misplacement, and contamination. Each of these can have significant consequences for the function and lifespan of electronic products.

Soldering Faults: The Leading Cause of Assembly Failures

Soldering is a critical step in joining components to the PCB. Poor solder joints are a primary source of electronics assembly defects. These can manifest in several ways:

- Cold Solder Joints: Occur when the solder does not properly melt, leading to weak electrical connections. They often appear dull or grainy.

- Solder Bridges: Excess solder creates unintended connections between adjacent pads or pins, potentially causing short circuits.

- Insufficient Solder: Too little solder results in incomplete coverage, which can cause intermittent connections or total failure.

- Excess Solder: Over-application can lead to bridging or mechanical stress on components.

These issues can be detected visually or through automated optical inspection (AOI). For a deeper look at inspection technologies, see this overview of electronics inspection methods.

Component Placement and Orientation Errors

Accurate placement of components is vital for circuit functionality. Errors in this stage can include:

- Misaligned Components: Parts not properly centered on their pads may not form reliable connections, leading to open circuits or mechanical stress.

- Wrong Orientation: Polarized components (like diodes and electrolytic capacitors) installed backwards can cause immediate failure.

- Incorrect Part Placement: Placing the wrong component in a location can result in unpredictable behavior or damage to the assembly.

These problems often arise from programming errors in pick-and-place machines, human oversight, or unclear assembly documentation. Preventing such mistakes requires robust process controls and thorough verification at each stage.

Surface Contamination and Its Effects on Reliability

Cleanliness is often overlooked but is essential for long-term reliability. Residues from solder flux, dust, or even fingerprints can create conductive paths or corrode metal surfaces over time. This can lead to intermittent failures that are difficult to diagnose.

Proper cleaning processes and the use of no-clean fluxes can help mitigate these risks. Regular inspection and testing are also important to ensure contaminants do not compromise the assembly.

Advanced Inspection and Testing for Defect Detection

As electronics become more complex, traditional visual inspection is often insufficient. Advanced methods such as X-ray imaging, in-circuit testing (ICT), and functional testing are increasingly used to identify hidden faults. These techniques can reveal issues like internal solder voids, hidden bridges, and micro-cracks that would otherwise go unnoticed.

For those seeking to understand the standards and techniques used in component testing, this resource on electronic component testing standards and advanced techniques provides a comprehensive overview.

Process Improvements to Reduce Assembly Defects

Minimizing errors in electronics manufacturing requires a combination of process optimization, staff training, and investment in inspection technology. Key strategies include:

- Implementing automated solder paste inspection and AOI systems to catch defects early.

- Regular calibration and maintenance of assembly equipment.

- Clear, up-to-date assembly documentation and labeling to prevent placement errors.

- Continuous training for operators and quality control personnel.

- Utilizing feedback from defect analysis to refine processes and prevent recurrence.

Understanding the copper plating process explained and how vias are made in PCBs can also help in identifying potential sources of defects related to board fabrication.

Frequently Asked Questions

What are the most common defects found in electronics assembly?

The most frequent issues include poor solder joints (such as cold joints and solder bridges), misaligned or incorrectly oriented components, and surface contamination. Each of these can lead to electrical failures, reduced reliability, or even complete device malfunction.

How can manufacturers detect hidden assembly defects?

In addition to visual inspection, manufacturers use automated optical inspection, X-ray imaging, in-circuit testing, and functional testing. These methods help uncover faults that are not visible to the naked eye, such as internal solder voids or micro-cracks.

What steps can be taken to prevent assembly errors?

Preventive measures include thorough process documentation, regular equipment maintenance, staff training, and the use of advanced inspection technologies. Continuous monitoring and analysis of defect data also enable ongoing improvements in manufacturing processes.

Why is surface cleanliness important in electronics assembly?

Residues and contaminants can cause corrosion, electrical leakage, or intermittent failures. Ensuring clean assembly surfaces through proper cleaning processes and material selection is vital for long-term reliability.

Conclusion: Building Reliable Electronic Products

Reducing electronics assembly defects is essential for delivering high-quality, dependable products. By understanding the root causes of common issues—whether related to soldering, component placement, or contamination—manufacturers can implement effective controls and inspection methods. Staying informed about the latest testing standards and process improvements will further enhance product reliability and customer satisfaction.

For additional insights into stencil printing and its impact on assembly quality, you might find this explanation of how stencil printing works helpful.