Selecting the most suitable base material for a printed circuit board (PCB) is a foundational step in electronics design and manufacturing. The substrate determines not only the mechanical stability of the board but also its electrical performance, thermal management, and long-term reliability. With a wide range of options available, understanding how to choose PCB substrate is essential for engineers, designers, and procurement teams aiming to optimize both product quality and cost.

This guide breaks down the key factors to consider when evaluating PCB base materials, including performance characteristics, application requirements, and industry standards. Whether you are developing consumer electronics, industrial controls, or high-frequency communication devices, making an informed substrate selection can prevent costly redesigns and ensure your product meets its intended performance targets.

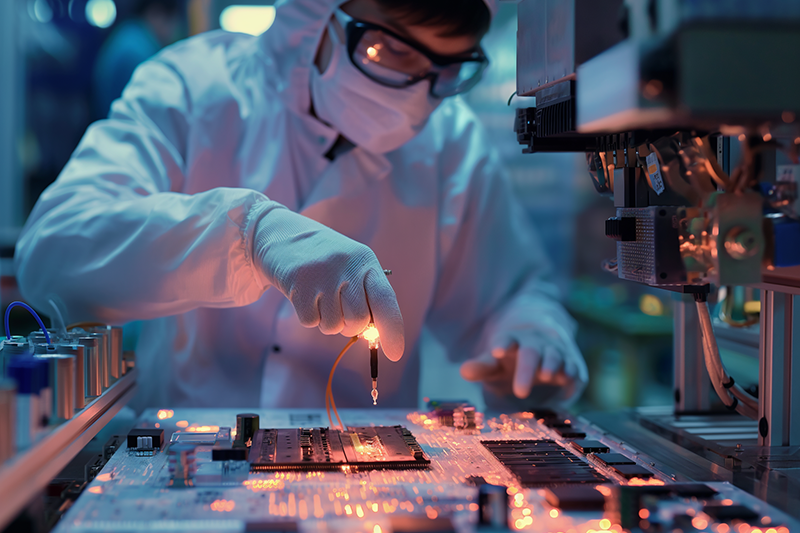

For a broader perspective on how substrate selection fits into the overall assembly process, you may also want to review electronic assembly best practices to ensure your design choices align with proven manufacturing workflows.

Understanding PCB Substrate Materials

The substrate is the insulating base layer of a PCB, providing both physical support and electrical insulation for copper traces and components. The most common materials include FR-4 (fiberglass-reinforced epoxy), polyimide, ceramics, and specialized high-frequency laminates. Each type offers distinct benefits and trade-offs in terms of cost, durability, and performance.

The choice of substrate impacts signal integrity, thermal dissipation, and the board’s ability to withstand environmental stresses. For example, FR-4 is widely used for its balance of affordability and performance, while ceramics are favored in applications requiring excellent thermal conductivity and high-frequency stability.

Key Factors in Choosing PCB Substrate

When considering how to choose PCB substrate, it’s important to evaluate several technical and practical aspects. Here are the most critical factors to guide your decision:

- Electrical Properties: Dielectric constant (Dk) and dissipation factor (Df) influence signal speed and loss, especially in high-frequency circuits.

- Thermal Performance: The substrate’s glass transition temperature (Tg) and thermal conductivity affect its ability to withstand heat during soldering and operation.

- Mechanical Strength: Flexural strength, tensile strength, and dimensional stability are vital for boards exposed to vibration, shock, or flexing.

- Moisture Absorption: Low absorption is crucial for boards used in humid or harsh environments to prevent degradation of electrical properties.

- Cost and Availability: While advanced materials offer superior performance, they may significantly increase production costs and lead times.

- Compliance and Standards: Ensure the substrate meets industry standards such as IPC, UL, and RoHS for safety and regulatory compliance.

Comparing Common PCB Substrate Types

The following table summarizes the most widely used PCB base materials, highlighting their core characteristics and typical applications:

| Material | Main Features | Typical Uses |

|---|---|---|

| FR-4 (Epoxy Glass) | Good electrical insulation, moderate cost, widely available | Consumer electronics, industrial controls |

| Polyimide | High thermal stability, flexible, resistant to chemicals | Flexible circuits, aerospace, automotive |

| Ceramic | Excellent thermal conductivity, low Dk, high frequency | RF/microwave, power electronics |

| Rogers (High-Frequency Laminate) | Low loss, stable Dk, tailored for RF | Telecom, radar, high-speed digital |

| Metal Core | Superior heat dissipation, rigid | LED lighting, power modules |

Application-Specific Considerations for PCB Substrate Selection

The intended use of your circuit board should heavily influence your substrate choice. For instance, high-frequency communication devices demand materials with low dielectric loss and stable electrical properties, while power electronics benefit from substrates with high thermal conductivity.

Environmental factors also play a role. Boards exposed to outdoor conditions or industrial environments may require substrates with enhanced moisture resistance and mechanical toughness. For flexible or wearable electronics, polyimide or other flexible substrates are often preferred due to their bendability and resilience.

If you’re interested in how different electronics packaging types interact with substrate choices, reviewing packaging strategies can provide additional context for your design decisions.

Balancing Performance and Cost in PCB Substrate Choices

One of the most common challenges is finding the right balance between technical requirements and budget constraints. While high-performance substrates like ceramics or Rogers laminates offer superior electrical and thermal properties, they can be significantly more expensive than standard FR-4.

For many mainstream products, FR-4 remains the default choice due to its versatility and cost-effectiveness. However, for specialized applications—such as RF, microwave, or high-power circuits—investing in advanced materials can be justified by improved reliability and performance.

It’s also important to consider manufacturing capabilities and supply chain factors. Some advanced substrates may require specialized fabrication processes or have longer lead times, which can impact project schedules.

Industry Standards and Quality Assurance

Ensuring your chosen substrate complies with recognized industry standards is critical for both safety and market acceptance. Look for materials that meet IPC specifications for performance and reliability, as well as UL certifications for flammability and safety. RoHS compliance is also essential for products intended for global markets.

Incorporating robust electronics quality control explained practices throughout the design and manufacturing process can further reduce the risk of failures related to substrate selection.

For a comprehensive overview of the entire electronics manufacturing process, including how substrate selection fits into each stage, see this detailed guide to electronic manufacturing services.

Frequently Asked Questions

What is the most commonly used PCB substrate?

FR-4, a fiberglass-reinforced epoxy laminate, is the most widely used PCB base material due to its balance of electrical performance, mechanical strength, and cost. It is suitable for a broad range of consumer and industrial applications.

How does substrate choice affect high-frequency circuit performance?

In high-frequency designs, the dielectric constant and loss tangent of the substrate have a significant impact on signal integrity and transmission losses. Specialized materials like Rogers laminates or ceramics are often chosen for their low loss and stable electrical properties in RF and microwave applications.

Can I use the same substrate for both rigid and flexible PCBs?

No, rigid boards typically use materials like FR-4, while flexible circuits require substrates such as polyimide or other flexible polymers. The choice depends on the mechanical and environmental demands of your application.