When it comes to creating efficient, cost-effective, and high-quality hardware products, the concept of design for assembly plays a crucial role. This article will delve into the principles of this approach, providing an understanding of its importance in the hardware industry.

Before we delve deeper, it might be useful to refer to this hardware product roadmap planning guide for a broader context on how design for assembly fits into the overall hardware development process.

Understanding the Concept of Design for Assembly

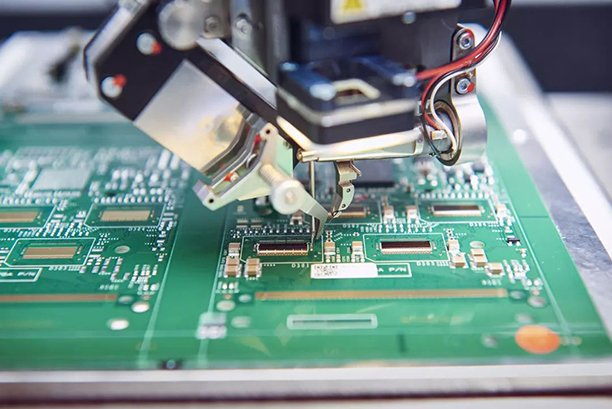

Design for assembly, often abbreviated as DFA, is a design philosophy focused on simplifying the product structure to reduce assembly costs and improve quality. The goal is to minimize the number of assembly operations by incorporating features that make it easier to grasp, orient, and insert parts.

Key Principles of Design for Assembly

Several principles guide the process of design for assembly in hardware. These principles aim to reduce the complexity of the assembly process, minimize the number of parts, and facilitate easy assembly.

Benefits of Implementing Design for Assembly

Applying design for assembly principles can lead to numerous benefits, including cost savings, improved product quality, and reduced time to market. It also fosters better collaboration between design and manufacturing teams, leading to more efficient processes and superior products.

For a deeper understanding of how these principles can be applied in real-world scenarios, you can refer to this concept prototyping for hardware guide.

In conclusion, design for assembly is a vital aspect of hardware design that can significantly impact the success of a product. By understanding and applying these principles, companies can create more efficient, cost-effective, and high-quality products.