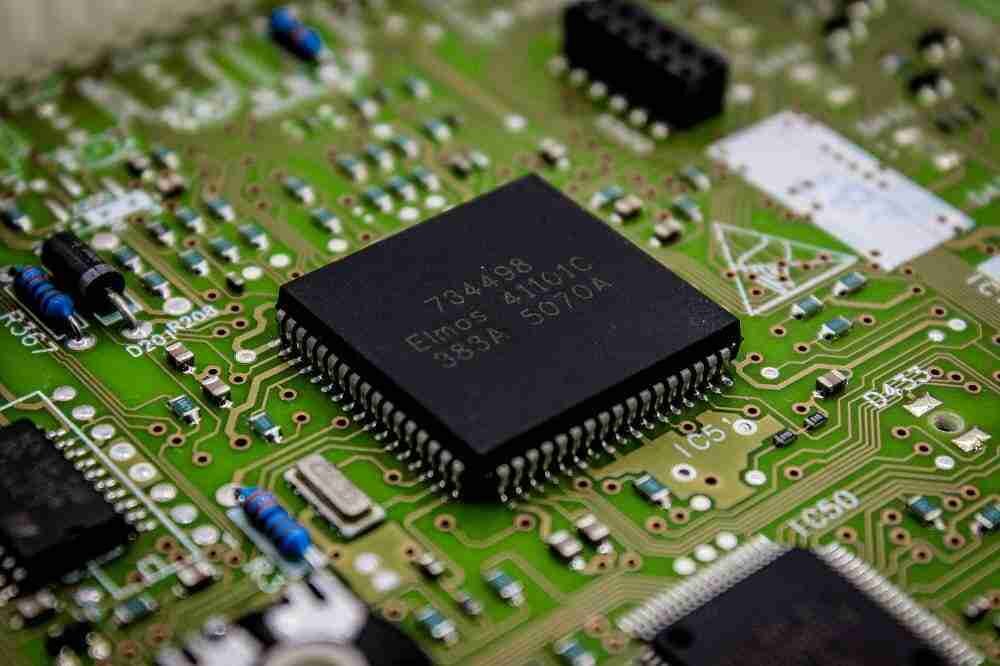

When it comes to the development of hardware, prototyping is a critical step. It allows engineers to test and refine their designs before moving into production. However, there are several common pitfalls that can derail this process. In this article, we’ll explore some of these pitfalls and provide tips on how to avoid them.

Before we delve deeper, consider reading our guide on how to test embedded hardware systems for a comprehensive understanding of the subject.

Not Planning for Production

One of the most common errors in hardware prototyping is not planning for production from the outset. This can lead to designs that are difficult or even impossible to manufacture at scale. To avoid this, it’s important to consider factors such as material availability, manufacturing processes, and cost from the very beginning of the design process.

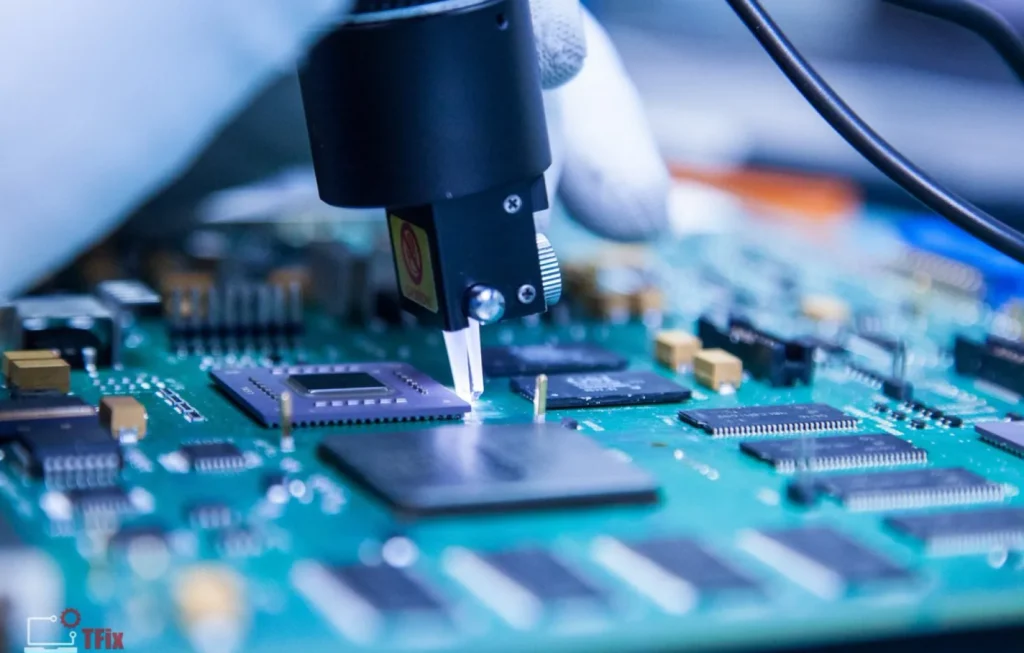

Overlooking Testing

Another common mistake is overlooking the importance of testing. Without thorough testing, it’s impossible to identify and address potential issues with a design. This can result in a final product that doesn’t meet quality standards or user expectations. For more on this, check out this descriptive anchor text.

Ignoring Feedback

Ignoring feedback is another pitfall to avoid. Feedback from users can provide invaluable insights into how a product is used in the real world and highlight potential areas for improvement. It’s important to take this feedback on board and use it to refine your design.

Conclusion

In conclusion, avoiding these common hardware prototyping mistakes can save time, money, and frustration. By planning for production, conducting thorough testing, and listening to feedback, you can create a successful hardware prototype that meets your goals and exceeds user expectations.