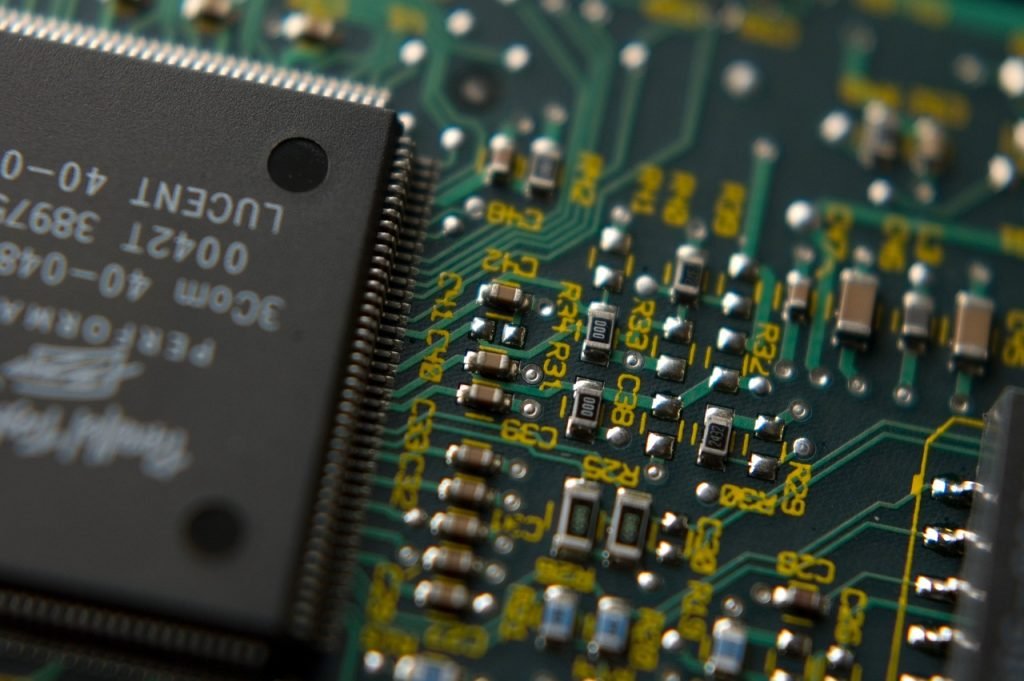

Printed Circuit Board (PCB) design involves a complex interplay of electrical and mechanical components. One of the key aspects that significantly influences the performance and reliability of these systems is grounding. This article delves into the significance of grounding in PCB design and why it should never be overlooked.

Understanding the hardware manufacturing handoff process is also crucial in this context.

Grounding and its Role in PCB Design

Grounding serves as a reference point for all electrical signals on the PCB. It helps in reducing noise, preventing damage from static electricity, and ensuring the proper functioning of the circuit.

Consequences of Improper Grounding

Incorrect grounding can lead to numerous issues, including signal interference, erratic behavior of the circuit, and even system failure. Therefore, it’s vital to implement proper grounding strategies during the PCB design process.

Best Practices for Grounding in PCB Design

Adopting best practices for grounding can significantly enhance the performance and reliability of your PCB. These include using a ground plane, minimizing the length of ground paths, and separating digital and analog grounds.

For more insights on hardware prototyping, you can visit this descriptive anchor text.

Author: Ethan Carter

Publication Date: 2025-11-08