In the modern world, where sustainability is a pressing concern, understanding how turnkey manufacturing supports recycling is crucial. This approach not only benefits the environment but also provides a competitive edge to exporters and importers seeking to meet increasing consumer demand for eco-friendly products. By integrating turnkey manufacturing processes with recycling initiatives, companies can achieve significant reductions in waste and resource consumption, paving the way for a sustainable future.

To fully comprehend the impact of turnkey manufacturing on recycling, we must first examine its role in the manufacturing sector. Turnkey solutions provide a comprehensive service, handling every aspect of production from design to delivery. This holistic approach ensures that recycling is seamlessly incorporated into each stage of the manufacturing process.

The Concept of Turnkey Manufacturing

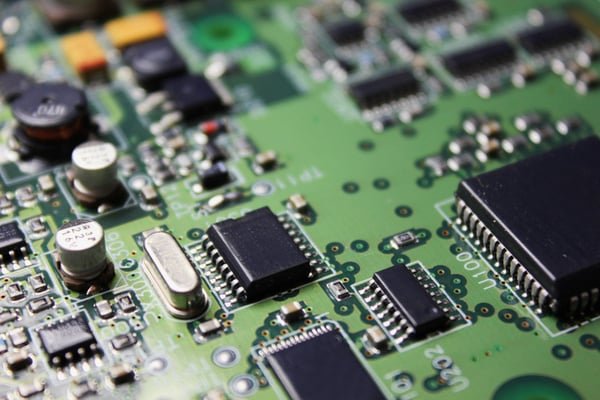

Turnkey manufacturing is a streamlined process where a single service provider manages the entire production cycle. This includes procurement, assembly, quality control, and logistics. By consolidating these functions, turnkey manufacturing enhances efficiency and reduces overhead costs. More importantly, it offers a unique opportunity to integrate recycling into the manufacturing process, making it an essential component of sustainable production.

Benefits of Turnkey Manufacturing in Recycling

The benefits of integrating recycling into turnkey manufacturing are manifold. For starters, it leads to reduced waste generation. By implementing recycling protocols at various stages of production, companies can minimize the amount of material that ends up in landfills. This not only conserves natural resources but also lowers disposal costs.

Furthermore, recycling in turnkey manufacturing can improve product design. By using recycled materials, manufacturers can create products that are both eco-friendly and cost-effective. This appeals to environmentally conscious consumers and helps companies meet regulatory standards for sustainability.

How Turnkey Manufacturing Enhances Recycling Efforts

Turnkey manufacturing enhances recycling efforts in several ways. Firstly, it allows for better resource management. By coordinating all aspects of production, manufacturers can optimize the use of materials and ensure that waste is minimized. This is particularly beneficial for exporters and importers who need to balance cost efficiency with sustainability.

Secondly, turnkey solutions enable manufacturers to implement closed-loop systems. These systems ensure that materials are continuously reused, reducing the need for virgin resources. By promoting recycling within the production process, companies can significantly lower their environmental impact.

Case Studies: Successful Recycling in Turnkey Manufacturing

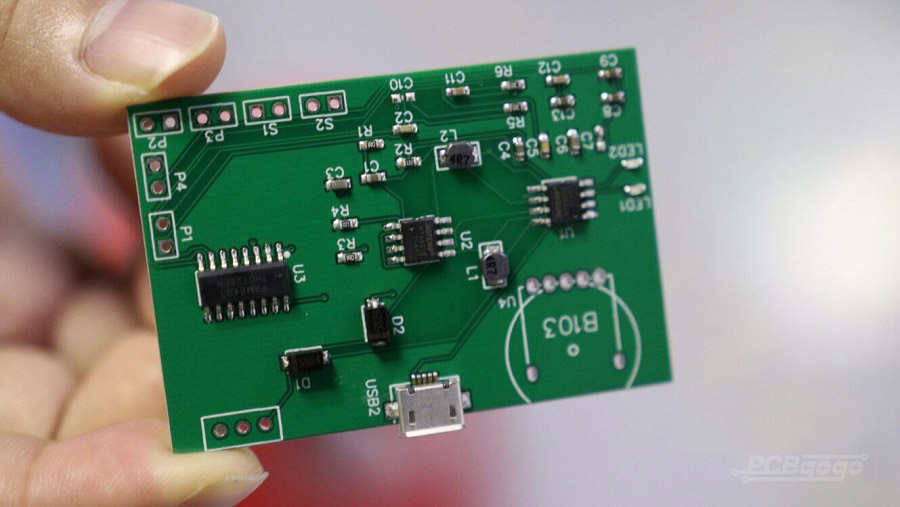

Several companies have successfully integrated recycling into their turnkey manufacturing processes. For example, a leading electronics manufacturer implemented a program to recycle electronic waste, resulting in a 30% reduction in raw material usage. This initiative not only saved costs but also positioned the company as a leader in sustainable manufacturing.

Another example is a textile company that utilized recycled fibers in its turnkey production process. By doing so, it reduced water and energy consumption by 40%, showcasing the potential for significant environmental benefits through recycling.

Challenges and Solutions in Integrating Recycling with Turnkey Manufacturing

While the integration of recycling into turnkey manufacturing offers numerous benefits, it is not without challenges. One major hurdle is the initial investment required to implement recycling systems. However, this can be offset by the long-term savings achieved through reduced material costs and waste management expenses.

Another challenge is the need for specialized expertise to manage recycling processes. Companies can overcome this by partnering with experienced turnkey service providers who have the necessary knowledge and resources to implement effective recycling strategies.

Future Trends in Turnkey Manufacturing and Recycling

The future of turnkey manufacturing and recycling is promising, with several trends emerging to support sustainable practices. One such trend is the use of advanced technologies, such as AI and IoT, to optimize recycling processes. These technologies can enhance efficiency by monitoring material usage and identifying areas for improvement.

Additionally, there is a growing emphasis on circular economy principles, which focus on designing products for durability and recyclability. By adopting these principles, turnkey manufacturers can create a sustainable production model that benefits both the environment and the economy.

Conclusion

In conclusion, understanding how turnkey manufacturing supports recycling is essential for companies looking to thrive in the modern marketplace. By embracing this approach, exporters and importers can achieve significant environmental and economic benefits. As the demand for sustainable products continues to rise, integrating recycling into turnkey manufacturing processes will become increasingly important.

For more insights on sustainable manufacturing practices, visit this guide.

FAQs

What is turnkey manufacturing?

Turnkey manufacturing refers to a comprehensive service where a single provider manages all aspects of production, from design to delivery, allowing for streamlined processes and efficient production cycles.

How does recycling benefit manufacturers?

Recycling benefits manufacturers by reducing waste, conserving resources, and lowering production costs. It also helps in meeting regulatory standards for sustainability and appeals to environmentally conscious consumers.

What are the challenges of integrating recycling with turnkey manufacturing?

Challenges include the initial investment required for recycling systems and the need for specialized expertise. However, these can be mitigated through partnerships with experienced turnkey service providers.

For more information on sustainable practices, check out green practices in turnkey PCB assembly.