In todays fast-paced global market, understanding the industry standards in turnkey manufacturing is crucial for exporters and importers aiming to maintain a competitive edge. The term ‘turnkey’ implies a comprehensive service where the provider takes full responsibility for all aspects of a project, from design to completion. For businesses involved in turnkey manufacturing, adhering to industry standards is not just a best practice; its a necessity.

What is Turnkey Manufacturing?

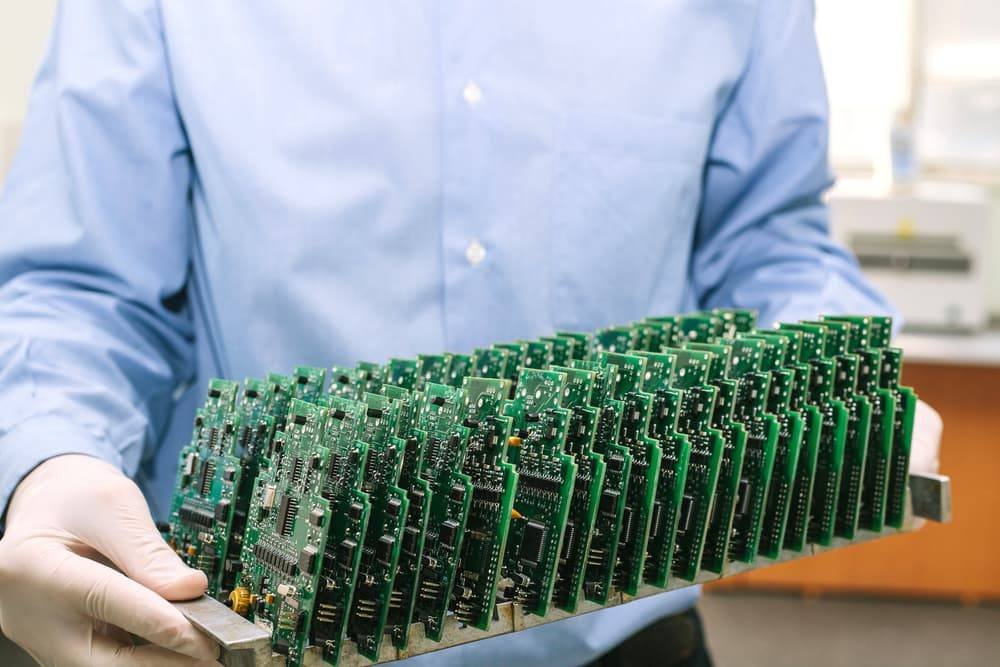

Turnkey manufacturing refers to a process where a single provider handles all phases of production, ensuring that the final product is ready for immediate use by the client. This approach minimizes the client’s involvement, allowing them to focus on core business activities while the manufacturer manages everything from procurement to quality assurance.

The Importance of Industry Standards

Industry standards in turnkey manufacturing are essential for ensuring quality, safety, and efficiency. Standards provide a framework that guides manufacturers in delivering consistent and reliable products. For businesses involved in international trade, adherence to these standards is critical to meet regulatory requirements and customer expectations.

Quality Assurance in Turnkey Manufacturing

A key component of industry standards is quality assurance. This involves systematic processes and procedures to ensure that the products meet the required specifications and quality benchmarks. Quality assurance not only improves product reliability but also enhances customer satisfaction.

Regulatory Compliance

Compliance with regulations is another vital aspect of turnkey manufacturing. Manufacturers must ensure that their processes and products comply with local and international laws, which often include environmental and safety standards. Non-compliance can lead to legal repercussions and damage to the businesss reputation.

Key Elements of Industry Standards

Supplier Management

Effective supplier management is essential in turnkey manufacturing. It involves selecting and managing suppliers who can meet the required quality and delivery standards. A strong supplier network ensures that the manufacturer can deliver the final product on time and within budget.

Continuous Improvement

Continuous improvement is a principle embedded in most industry standards. It involves regularly assessing and enhancing processes to increase efficiency and reduce waste. This proactive approach helps manufacturers stay competitive and responsive to changing market demands.

Risk Management

Risk management is critical in the turnkey manufacturing process. Identifying and mitigating potential risks ensures that the manufacturing process runs smoothly and reduces the likelihood of delays or defects.

Benefits of Adhering to Industry Standards

Increased Efficiency

Adhering to industry standards helps manufacturers streamline their processes, leading to increased efficiency. This efficiency translates into faster production times and lower costs, providing a competitive advantage in the global market.

Enhanced Reputation

Compliance with industry standards enhances a companys reputation. Clients and partners are more likely to trust a manufacturer that consistently delivers high-quality, compliant products.

Market Access

Meeting industry standards is often a prerequisite for accessing certain markets, especially in regions with strict regulatory requirements. Compliance ensures that products can be sold in multiple markets without additional modifications.

Challenges in Maintaining Industry Standards

Keeping Up with Changes

One of the main challenges in turnkey manufacturing is keeping up with changing standards and regulations. Manufacturers must continuously monitor updates and adjust their processes accordingly to remain compliant.

Cost Implications

Implementing and maintaining industry standards can be costly. However, the long-term benefits of compliance, such as reduced risk and increased market access, often outweigh the initial investment.

Conclusion

In conclusion, understanding and adhering to industry standards in turnkey manufacturing is essential for businesses aiming to succeed in the global market. These standards ensure quality, safety, and efficiency, ultimately leading to improved customer satisfaction and business growth.

FAQ

What are turnkey manufacturing services?

Turnkey manufacturing services involve a provider managing all aspects of the production process, ensuring the final product is ready for use without client intervention.

Why are industry standards important?

Industry standards are important because they ensure quality, safety, and compliance with regulations, which are crucial for market access and customer trust.

How do industry standards impact exporters and importers?

Industry standards impact exporters and importers by ensuring that products meet international quality and safety requirements, facilitating smoother trade across borders.

For further reading on turnkey manufacturing services, visit HiTek Quality’s comprehensive guide.

Learn more about turnkey procurement in this insightful article by BL International.

Explore the differences between prototyping and mass production in this detailed comparison.

Discover the importance of green practices in manufacturing here.