In the fast-paced world of electronics, the role of big data in turnkey electronics manufacturing has become increasingly significant. As more companies aim to streamline production and enhance efficiency, turnkey solutions have emerged as a vital strategy. Big data plays a pivotal role in this transformation, offering valuable insights and driving innovation.

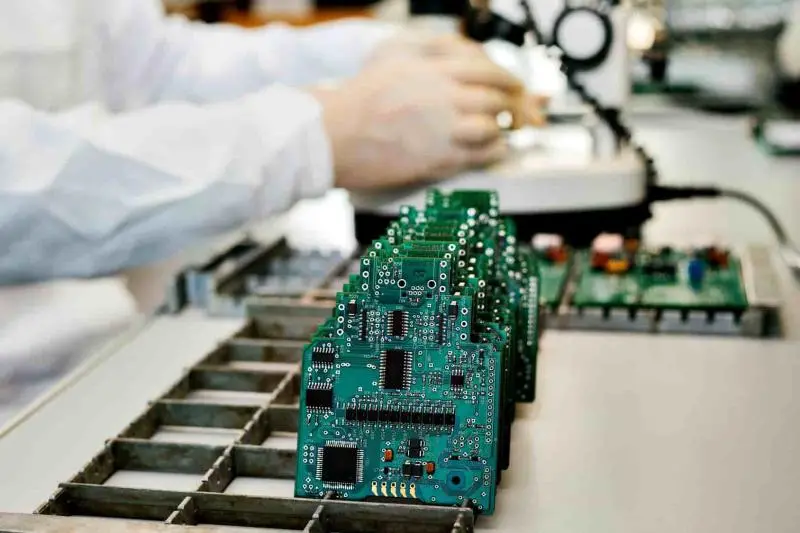

Understanding Turnkey Electronics Manufacturing

Turnkey electronics manufacturing refers to a comprehensive service where a single provider handles all aspects of production, from design and prototyping to mass production and shipping. This approach allows companies to focus on their core competencies while outsourcing complex manufacturing processes.

How Big Data Transforms Turnkey Solutions

Big data is revolutionizing the way turnkey solutions are implemented in electronics manufacturing. By collecting and analyzing vast amounts of data, manufacturers can make informed decisions, optimize processes, and reduce costs. The integration of big data into turnkey solutions offers numerous benefits, including improved product quality, enhanced efficiency, and faster time-to-market.

Benefits of Big Data in Electronics Manufacturing

Enhanced Quality Control

One of the primary benefits of big data in electronics manufacturing is enhanced quality control. By analyzing data from various stages of production, manufacturers can identify defects early, ensure consistent quality, and reduce the likelihood of product recalls. This proactive approach not only improves product reliability but also boosts customer satisfaction.

Optimized Supply Chain Management

Big data plays a crucial role in optimizing supply chain management. By analyzing data from suppliers, manufacturers can predict demand fluctuations, manage inventory more efficiently, and reduce lead times. This optimization leads to cost savings and ensures that products are delivered to customers promptly.

Predictive Maintenance and Downtime Reduction

Predictive maintenance is another area where big data proves invaluable. By monitoring machinery and equipment data, manufacturers can predict when maintenance is needed, reducing downtime and preventing costly breakdowns. This proactive approach increases equipment lifespan and ensures uninterrupted production.

Challenges in Implementing Big Data

Data Security and Privacy Concerns

Despite its benefits, implementing big data in electronics manufacturing comes with challenges. Data security and privacy concerns are significant issues that manufacturers must address. Protecting sensitive information and ensuring compliance with regulations is crucial to maintaining trust with customers and partners.

Integration with Existing Systems

Another challenge is integrating big data solutions with existing systems. Manufacturers must ensure that new technologies seamlessly integrate with their current infrastructure to avoid disruptions and maximize the benefits of big data.

Future Trends in Big Data and Manufacturing

The future of big data in electronics manufacturing looks promising. With advancements in artificial intelligence and machine learning, manufacturers can expect even more sophisticated data analysis and decision-making capabilities. These technologies will further enhance product quality, reduce costs, and accelerate innovation.

The Role of AI and Machine Learning

AI and machine learning are set to play a crucial role in the future of electronics manufacturing. By leveraging these technologies, manufacturers can gain deeper insights from data, automate complex processes, and improve decision-making. This integration will drive efficiency and innovation in the industry.

Increased Focus on Sustainability

Sustainability is becoming a key focus for manufacturers. Big data can help companies achieve sustainability goals by analyzing energy consumption, optimizing resource usage, and reducing waste. This focus on sustainability not only benefits the environment but also enhances brand reputation and customer loyalty.

Conclusion

The role of big data in turnkey electronics manufacturing is transformative. By leveraging data-driven insights, manufacturers can enhance quality, optimize processes, and drive innovation. As the industry evolves, the integration of big data will continue to play a crucial role in shaping the future of electronics manufacturing.

Frequently Asked Questions

What is turnkey electronics manufacturing?

Turnkey electronics manufacturing is a comprehensive service where a single provider manages all aspects of production, from design to delivery.

How does big data enhance quality control?

Big data enhances quality control by analyzing production data to identify defects early, ensuring consistent quality, and reducing product recalls.

What are the challenges of implementing big data?

Challenges of implementing big data include data security and privacy concerns, as well as integrating new technologies with existing systems.

For more insights on turnkey contract manufacturing and turnkey PCB assembly, check out these resources.