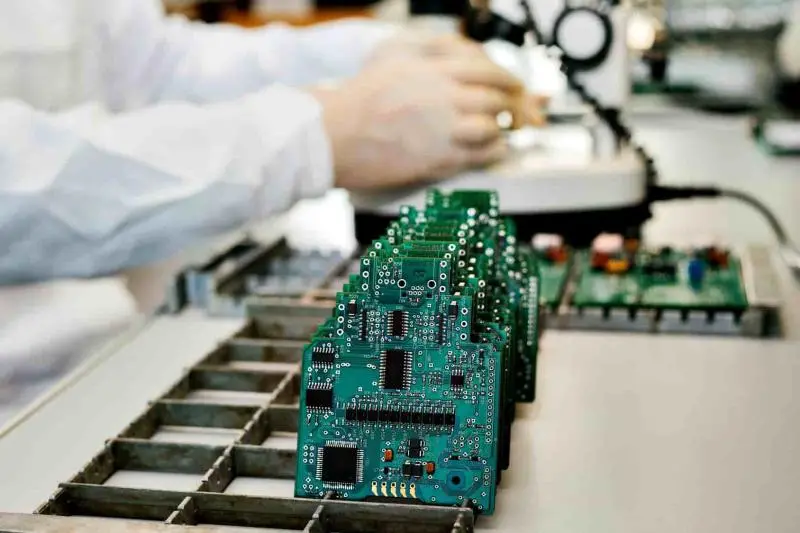

In the world of turnkey electronics, the processes of potting and encapsulation are crucial for ensuring the durability and reliability of electronic components. These methods are not only pivotal in safeguarding the integrity of electronic assemblies but also in enhancing their performance. As the demand for reliable and durable electronic devices continues to rise, understanding these processes becomes increasingly important for both manufacturers and consumers.

What is Potting in Electronics?

Potting involves filling an electronic assembly with a solid or gelatinous compound for vibration dampening and protection against moisture and corrosion. This process is essential in turnkey electronics, as it provides a protective barrier on the components, enhancing their longevity.

Materials Used in Potting

The materials commonly used for potting include epoxy, silicone, and polyurethane. Each material offers unique benefits, such as thermal resistance or flexibility, making them suitable for different applications.

Benefits of Potting

Potting offers numerous advantages, including protection from environmental factors, improved thermal management, and enhanced mechanical strength. These benefits ensure that the electronic components function optimally even under challenging conditions.

Exploring Encapsulation in Electronics

Encapsulation is a process similar to potting, but it typically involves covering the entire electronic assembly with a protective layer. This method is often used to protect semiconductors and other sensitive components from environmental damage.

Encapsulation Materials

Like potting, encapsulation also utilizes materials such as epoxy and silicone. These materials are chosen based on their ability to provide a robust protective layer while maintaining the functionality of the electronic assembly.

Advantages of Encapsulation

The primary benefits of encapsulation include enhanced protection against physical damage, improved electrical insulation, and resistance to chemical exposure. This makes encapsulation a preferred choice in environments where electronic components are exposed to harsh conditions.

Applications in Turnkey Electronics

In the context of turnkey electronics, both potting and encapsulation play vital roles in ensuring the reliability and performance of the final product. These processes are integral to the manufacturing of consumer electronics, automotive components, and industrial equipment.

Consumer Electronics

For consumer electronics, such as smartphones and wearable devices, potting and encapsulation provide the necessary protection against everyday wear and tear, as well as water and dust ingress.

Automotive Components

In the automotive industry, electronic components are exposed to extreme temperatures and vibrations. Here, potting and encapsulation help maintain the functionality and reliability of critical systems.

Industrial Equipment

Industrial equipment often operates in harsh environments, making the protection offered by potting and encapsulation essential for sustaining operations and minimizing downtime.

Challenges and Considerations

While the benefits of potting and encapsulation are clear, there are challenges to consider. These include the selection of appropriate materials, the impact on thermal management, and the potential for increased production costs.

Material Selection

Choosing the right material for potting or encapsulation is crucial. Factors such as thermal conductivity, chemical resistance, and flexibility must be considered to ensure optimal performance.

Thermal Management

Both potting and encapsulation can affect the thermal properties of electronic assemblies. It is essential to consider how these processes might impact heat dissipation and overall thermal management.

Cost Implications

While these processes add value to the final product, they can also increase production costs. Manufacturers must balance the benefits with the associated expenses to maintain competitiveness.

Future Trends in Potting and Encapsulation

As technology advances, so too do the methods and materials used in potting and encapsulation. Emerging trends include the development of eco-friendly materials and the integration of smart technologies to improve the efficiency of these processes.

Eco-Friendly Materials

With a growing emphasis on sustainability, manufacturers are exploring biodegradable and environmentally friendly potting compounds that reduce the environmental impact of electronic waste.

Smart Technologies

The integration of smart technologies in turnkey electronics is paving the way for more efficient and precise potting and encapsulation processes. These advancements are set to improve the quality and performance of electronic products.

Conclusion

In conclusion, potting and encapsulation in turnkey electronics are essential processes that ensure the durability and reliability of electronic components. By understanding the benefits and challenges associated with these methods, manufacturers can make informed decisions to enhance the performance and longevity of their products.

FAQs

What is the difference between potting and encapsulation?

While both processes protect electronic components, potting involves filling the assembly with a protective compound, whereas encapsulation covers the entire assembly with a protective layer.

Why are potting and encapsulation important in electronics?

These processes offer protection against environmental factors, enhance thermal management, and improve the mechanical strength of electronic components.

What materials are commonly used in potting and encapsulation?

Common materials include epoxy, silicone, and polyurethane, chosen for their thermal resistance, flexibility, and protective qualities.