In today’s fast-paced electronics industry, turnkey services for conformal coating are revolutionizing how businesses handle the protective coating of electronic components. These services are crucial for exporters and importers who aim to enhance product quality and reliability. By understanding the ins and outs of these turnkey services, businesses can stay ahead in the competitive market.

What are Turnkey Services for Conformal Coating?

The term turnkey services refers to comprehensive solutions provided by manufacturers that cover all aspects of a project from start to finish. When applied to conformal coating, these services involve the complete process of applying protective coatings to electronic assemblies. This ensures that the components are safeguarded against environmental damage and electrical failures.

Key Benefits of Turnkey Conformal Coating Services

Choosing turnkey services offers several advantages, including:

- Efficiency: Streamlining the process reduces lead times and increases production speed.

- Quality Assurance: Ensures consistent application of coatings, enhancing product reliability.

- Cost-Effectiveness: Reduces the need for multiple vendors, lowering overall costs.

Why Conformal Coating is Essential

Conformal coating plays a vital role in protecting electronic components from moisture, dust, chemicals, and temperature extremes. This protective layer extends the life of the devices and ensures optimal performance.

For exporters and importers, implementing conformal coating is crucial for maintaining product integrity during transit and storage, especially in diverse environmental conditions.

Types of Conformal Coatings

There are several types of conformal coatings, each suited for specific applications:

- Acrylic Coatings: Easy to apply and remove, offering good moisture resistance.

- Silicone Coatings: Flexible and resistant to high temperatures.

- Urethane Coatings: Provide strong chemical and abrasion resistance.

- Epoxy Coatings: Offer excellent protection against harsh environmental conditions.

Steps Involved in Turnkey Conformal Coating Services

The process of turnkey conformal coating involves several critical steps:

1. Design and Consultation

Understanding client requirements and choosing the appropriate coating type.

2. Material Selection

Selecting the best coating material based on the application and environmental factors.

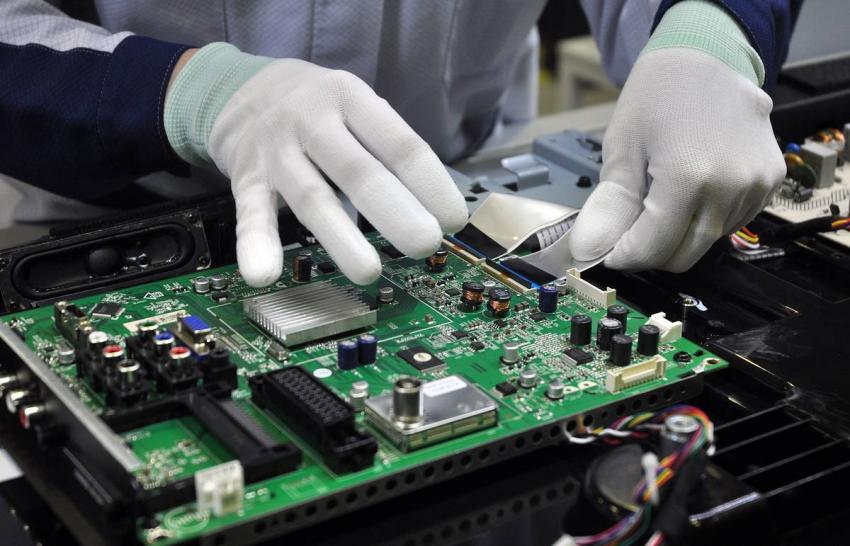

3. Application Process

Using advanced techniques such as spray, dip, or brush application to ensure even coating.

4. Quality Control

Conducting thorough inspections to ensure the coating meets industry standards.

Choosing the Right Turnkey Service Provider

When selecting a turnkey service provider, consider the following:

- Experience: Look for providers with a proven track record in conformal coating.

- Technology: Ensure they use state-of-the-art equipment for precise coating.

- Customer Support: Choose a provider that offers excellent support and communication.

Partnering with a reliable provider can significantly enhance your product’s quality and market appeal. For more insights on choosing the right service, visit Green Circuits.

Industry Applications of Turnkey Conformal Coating Services

Turnkey conformal coating services are utilized across various industries, including:

- Automotive: Protecting electronic systems in vehicles.

- Aerospace: Safeguarding avionics and other critical components.

- Consumer Electronics: Ensuring durability and performance of gadgets.

Overcoming Challenges in Conformal Coating

While conformal coating offers many benefits, challenges such as proper material selection and application techniques must be addressed. Partnering with experienced providers can help overcome these challenges effectively.

Advancements in Conformal Coating Technologies

Recent advancements have led to more efficient and environmentally friendly coating processes. Innovations such as automated coating systems and advanced materials are setting new industry standards.

FAQ Section

What is the importance of conformal coating in electronics?

Conformal coating is crucial for protecting electronic components from environmental damage, ensuring long-term reliability and performance.

How do turnkey services benefit exporters and importers?

By providing comprehensive solutions, turnkey services streamline operations, reduce costs, and improve product quality, making them ideal for exporters and importers.

What should I look for in a turnkey service provider?

Consider factors such as experience, technology, and customer support when choosing a turnkey service provider to ensure optimal results.

For further reading on electronics manufacturing, check out Electronics Prototyping vs Mass Production and Turnkey Procurement vs Customer-Supplied Parts.