In the fast-paced world of electronics manufacturing, maintaining product quality while optimizing efficiency is crucial. One key approach to achieving this balance is through flying probe testing turnkey services. These services provide a comprehensive solution for testing and verifying electronic devices, ensuring they meet the necessary standards before reaching the market.

Understanding Flying Probe Testing

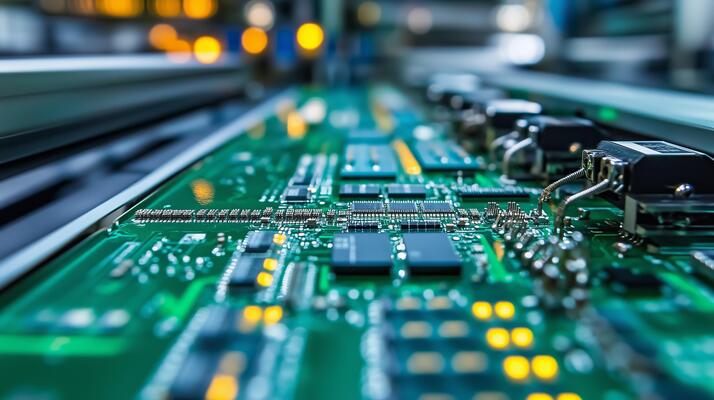

Flying probe testing is a method used to test printed circuit boards (PCBs) and other electronic components without requiring a physical test fixture. This approach uses multiple probes that move freely over the board to test for electrical performance, connectivity, and other parameters. It’s an ideal solution for prototypes and low-volume production where creating a custom fixture would be costly and time-consuming.

The Benefits of Turnkey Services

Turnkey services in electronics manufacturing refer to solutions where the provider handles all aspects of a project, from design to production, testing, and delivery. This comprehensive approach ensures consistency and quality throughout the manufacturing process, making it a popular choice for both exporters and importers. Learn more about turnkey services here.

Why Choose Flying Probe Testing Turnkey Services?

Choosing flying probe testing turnkey services offers several advantages. Firstly, it reduces the time and cost associated with test development, especially for small production runs. Additionally, it provides flexibility, as changes in the design can be accommodated quickly without the need for new test fixtures.

Improved Quality Assurance

By integrating testing into the turnkey process, manufacturers can ensure that all products meet the required specifications. This integration helps in identifying and addressing issues early in the production cycle, leading to better product reliability and customer satisfaction.

Applications of Flying Probe Testing

This testing method is versatile and can be applied to various stages of electronics manufacturing. It’s particularly beneficial for prototype testing, where quick iteration and feedback are necessary. Additionally, it’s used in quality assurance for mass production, ensuring each unit meets the required standards.

Key Industries Utilizing Flying Probe Testing

Industries such as telecommunications, automotive, and consumer electronics heavily rely on flying probe testing turnkey services to maintain high-quality standards. These sectors require precise and reliable components, making rigorous testing essential.

Cost-Effectiveness of Turnkey Solutions

While the initial investment in turnkey solutions might be higher, the long-term benefits outweigh the costs. By streamlining the production and testing processes, companies can reduce waste, lower production costs, and improve time-to-market.

Streamlined Production Process

Turnkey services offer a streamlined production process, where all stages are managed by a single provider. This approach reduces the risk of miscommunication and errors, ensuring a smooth transition from design to product delivery. For more insights on turnkey manufacturing processes, check this DFX in Turnkey Manufacturing article.

Challenges and Considerations

While flying probe testing turnkey services offer numerous benefits, there are challenges to consider. For instance, the precision of the probes can be affected by environmental factors, and the complexity of the board design can influence the testing process. Manufacturers need to ensure that they work with experienced providers who can address these challenges effectively.

Choosing the Right Service Provider

Selecting the right service provider is crucial for success. Companies should look for providers with a proven track record, expertise in the specific industry, and the ability to customize solutions to meet unique needs.

The Future of Flying Probe Testing

As technology continues to evolve, so does the field of flying probe testing. Innovations in probe technology, automation, and data analytics are expected to enhance the capabilities of these services, making them even more integral to electronics manufacturing.

Embracing Technological Advancements

Manufacturers must stay updated with the latest advancements in testing technologies to remain competitive. Investing in modern equipment and software that supports advanced testing protocols can help companies maintain an edge in the market.

Case Studies: Successful Implementations

Several companies have successfully implemented flying probe testing turnkey services to improve their manufacturing processes. These case studies highlight the benefits of adopting such solutions and provide valuable insights for other businesses considering similar strategies.

Real-World Examples

For example, a leading telecommunications company utilized flying probe testing to enhance its product reliability, resulting in a significant reduction in defects and returns. Similarly, an automotive parts manufacturer achieved faster production cycles and improved quality assurance through turnkey services.

Conclusion

In conclusion, flying probe testing turnkey services offer a powerful solution for electronics manufacturers looking to improve quality and efficiency. By embracing these services, companies can ensure their products meet the highest standards, reduce time-to-market, and enhance customer satisfaction.

Faq

What is flying probe testing? Flying probe testing is a method used to test electronic circuit boards without a physical test fixture, using probes that move over the board to test its functionality.

Why choose turnkey services? Turnkey services provide a comprehensive solution from design to delivery, ensuring consistency and quality in the manufacturing process.

How can flying probe testing benefit my business? This testing method can reduce costs, improve quality assurance, and offer flexibility in production processes, making it ideal for small runs and prototypes.

Further Reading

To explore more about turnkey solutions, you can visit this external resource.