In today’s fast-paced world of technology, businesses are constantly seeking out low cost turnkey PCB assembly solutions to streamline their operations and reduce overheads. The demand for cost-effective and efficient manufacturing processes has never been higher. Importers and exporters across the globe are particularly interested in these solutions to remain competitive in the marketplace.

The concept of turnkey PCB assembly refers to the process where a single service provider handles the entire production cycle, from component procurement to final assembly. This approach not only simplifies the production process but also significantly reduces costs. By opting for turnkey solutions, businesses can benefit from bulk purchasing, reduced labor costs, and improved efficiency.

What is Turnkey PCB Assembly?

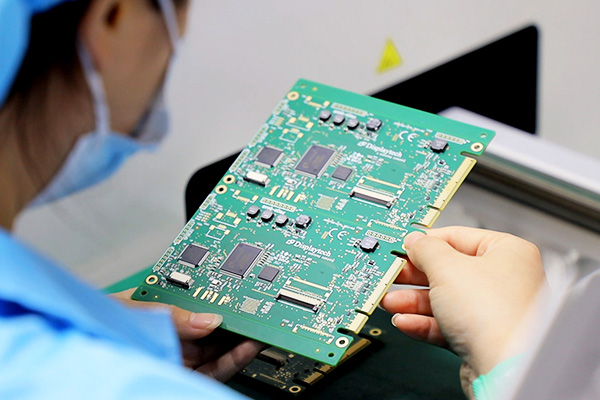

Turnkey PCB assembly is a comprehensive service where all stages of PCB production are managed by one entity. This includes the sourcing of components, manufacturing, assembly, testing, and quality control. This holistic approach ensures that businesses can focus on their core competencies while the service provider takes care of the production nuances.

Benefits of Choosing Turnkey Solutions

One of the primary benefits of turnkey solutions is cost reduction. By consolidating the entire process under one roof, businesses can achieve significant savings. Additionally, this approach ensures faster turnaround times, as all stages are streamlined and managed efficiently.

Another advantage is the reduction in logistical complexities. With a single point of contact, communication becomes seamless, reducing the risk of errors and misunderstandings. This not only improves the quality of the final product but also enhances customer satisfaction.

How to Implement Low Cost Turnkey PCB Assembly Solutions

For businesses looking to implement low cost turnkey PCB assembly solutions, it’s essential to partner with a reputable service provider. Look for companies that have a proven track record, offer competitive pricing, and possess the necessary certifications and quality standards.

Additionally, businesses should consider the geographical location of the service provider. Opting for a provider closer to the target market can further reduce shipping and logistical costs. It’s also crucial to ensure that the provider has a robust supply chain management system in place to prevent delays and bottlenecks.

Key Considerations for Importers and Exporters

Importers and exporters should be aware of the regulatory requirements in their respective markets. Compliance with these regulations is crucial to avoid legal complications and potential fines. Partnering with a service provider familiar with these regulations can be a significant advantage.

Moreover, businesses should consider the long-term implications of their manufacturing decisions. While cost is an essential factor, it’s equally important to ensure that the quality of the final product meets the expectations of the end-users.

Challenges in Turnkey PCB Assembly

While there are numerous benefits to turnkey PCB assembly, there are also challenges that businesses need to be aware of. One of the primary challenges is maintaining consistent quality across all stages of production. It’s essential to have stringent quality control measures in place to ensure that the final product meets the required standards.

Another challenge is the risk of dependency on a single provider. While turnkey solutions simplify the process, they also mean that businesses are reliant on one entity for their production needs. It’s crucial to have contingency plans in place to address potential disruptions in the supply chain.

The Role of Technology in Turnkey Solutions

Advancements in technology have played a significant role in the evolution of turnkey solutions. Automated processes, real-time monitoring, and advanced analytics have made it possible to enhance efficiency and reduce costs further. Businesses should leverage these technological advancements to stay ahead of the competition.

For more insights on how technology impacts turnkey manufacturing, consider exploring automated inspection processes in the industry.

Conclusion

In conclusion, low cost turnkey PCB assembly solutions offer a viable pathway for businesses to enhance their operations and reduce costs. By partnering with the right provider, leveraging technology, and understanding the complexities of the market, businesses can achieve significant benefits. As the demand for efficient and affordable manufacturing solutions continues to grow, importers and exporters must stay informed and proactive in their approach.

FAQs

What are the benefits of turnkey PCB assembly?

Turnkey PCB assembly offers several benefits, including cost reduction, streamlined processes, and improved quality control. By consolidating the production process, businesses can achieve faster turnaround times and enhance efficiency.

How can businesses reduce costs in PCB assembly?

Businesses can reduce costs by opting for turnkey solutions, partnering with reputable providers, leveraging technology, and ensuring compliance with regulatory requirements. Additionally, considering the geographical location of the provider can further reduce logistical costs.

What role does technology play in turnkey solutions?

Technology plays a crucial role in enhancing the efficiency of turnkey solutions. Automated processes, real-time monitoring, and advanced analytics help businesses reduce costs and improve the quality of the final product.