When it comes to the world of electronics manufacturing, selecting the right partner is crucial. The key factors in choosing a turnkey electronics partner can determine the success of your product and the efficiency of your supply chain. A well-chosen partner not only ensures the quality of your products but also helps in reducing costs and time-to-market.

In this article, we will explore the key factors that exporters and importers should consider when selecting a turnkey electronics partner. By understanding these factors, businesses can make informed decisions that align with their goals and ensure a successful collaboration.

Understanding Turnkey Electronics Solutions

Turnkey electronics solutions refer to a comprehensive approach where the partner takes care of all aspects of production, from design to delivery. This model offers a one-stop-shop for businesses looking to streamline their operations and focus on their core competencies. By outsourcing to a turnkey provider, companies can benefit from reduced overhead and improved cost efficiency.

Why Choose a Turnkey Partner?

Choosing a turnkey partner can bring numerous advantages. These include access to advanced technology, expertise in manufacturing, and the ability to scale production quickly. Additionally, turnkey partners often have established relationships with suppliers, enabling them to source materials at competitive prices. This can lead to significant cost savings for businesses.

Expertise and Experience

One of the most critical key factors in choosing a turnkey electronics partner is their expertise and experience. A partner with a proven track record in the industry can offer valuable insights and guidance throughout the manufacturing process. They understand the nuances of electronics production and can help navigate potential challenges.

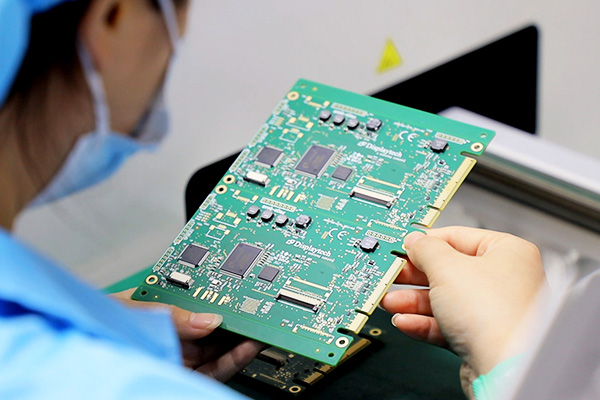

Quality Assurance

Quality assurance is paramount in electronics manufacturing. A reliable turnkey partner should have robust quality control measures in place to ensure that each product meets the required standards. This includes automated inspection systems and rigorous testing protocols. For more on how this is achieved, you can read about inspection in turnkey electronics.

Scalability and Flexibility

As businesses grow, their manufacturing needs may change. A good turnkey partner should offer scalability and flexibility to accommodate these changes. This means being able to increase production volumes without compromising on quality or delivery times.

Cost Considerations

Cost is a significant consideration for any business. A turnkey partner should provide transparent pricing and work with you to identify cost-saving opportunities throughout the production process. By leveraging their industry relationships, they can often secure better pricing on components and materials.

Technology and Innovation

The electronics industry is constantly evolving, with new technologies emerging regularly. A turnkey partner should stay at the forefront of these developments, offering innovative solutions that enhance product performance and functionality. For insights into how turnkey partners maintain consistent product quality, visit consistent product quality.

Supply Chain Management

Effective supply chain management is another key factor in choosing a turnkey electronics partner. The partner should have established processes for managing suppliers, logistics, and inventory. This ensures a smooth flow of materials and minimizes the risk of delays or disruptions.

Communication and Collaboration

Clear communication and collaboration are essential for a successful partnership. A turnkey partner should be responsive and proactive in addressing your needs and concerns. They should work closely with you to align their processes with your business objectives.

Customer Support

Customer support is an integral part of the partnership. A reliable turnkey partner should offer ongoing support and assistance, even after the production is complete. This includes handling any post-production issues and providing guidance on future projects.

Compliance and Certifications

Compliance with industry standards and certifications is crucial in electronics manufacturing. A turnkey partner should adhere to relevant regulations and possess the necessary certifications, ensuring that your products meet all legal and safety requirements.

Final Thoughts

Selecting the right turnkey electronics partner is a strategic decision that can have a lasting impact on your business. By considering the key factors outlined in this article, you can identify a partner that aligns with your goals and helps drive your success. Remember, a strong partnership is built on trust, communication, and shared objectives.

FAQs

What is a turnkey electronics partner?

A turnkey electronics partner is a company that provides comprehensive solutions for electronics manufacturing, handling all aspects from design to delivery.

Why is quality assurance important?

Quality assurance ensures that products meet the required standards and are free from defects, which is crucial for customer satisfaction and brand reputation.

How can a turnkey partner help reduce costs?

A turnkey partner can reduce costs through their industry expertise, established supplier relationships, and efficient production processes.

For more information on the benefits and limitations of turnkey electronics manufacturing, visit turnkey electronics benefits.