In today’s rapidly advancing world, electronics manufacturing for medical devices plays a crucial role in enhancing healthcare technology. This industry is pivotal in creating devices that not only save lives but also improve the quality of life. With a strong emphasis on precision and reliability, this field has seen a surge in innovation and demand. Understanding the complexities of this industry is essential for anyone involved, especially exporters and importers who play a significant role in the global supply chain.

Understanding the Basics of Electronics Manufacturing

The process of electronics manufacturing involves designing, producing, and assembling electronic components and systems. For medical devices, this means adhering to strict regulatory standards and ensuring the highest quality of production. The integration of cutting-edge technology in manufacturing processes has transformed this industry, making it more efficient and reliable.

The Importance of Quality in Medical Devices

Quality is paramount in the production of medical devices. These devices are often used in critical applications, where failure is not an option. As such, manufacturers must adhere to stringent quality control measures. This includes thorough testing and validation of products before they reach the market. For more on how automated inspection plays a role in ensuring quality, visit this article.

Regulatory Compliance

Regulatory compliance is another critical aspect of electronics manufacturing for medical devices. Manufacturers must comply with international standards and regulations, such as ISO 13485, which ensures that products meet both customer and regulatory requirements. Compliance not only ensures product safety and efficacy but also facilitates international trade by meeting the standards of different countries.

Technological Advancements in Electronics Manufacturing

The field of electronics manufacturing is continuously evolving, with new technologies emerging that enhance both the production process and the final product. Innovations such as automation, artificial intelligence, and machine learning are revolutionizing the industry.

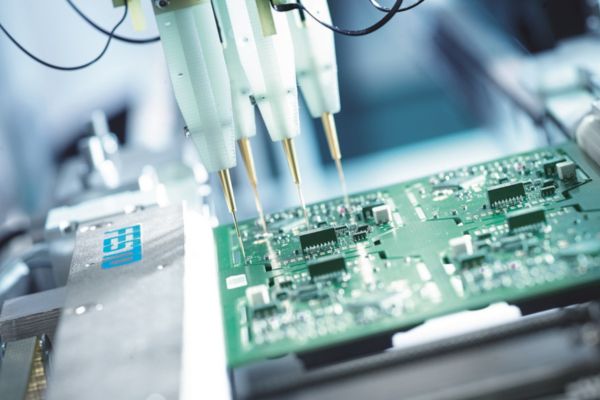

Automation and Efficiency

Automation is a key factor in improving efficiency and reducing human error in manufacturing. Automated systems can perform repetitive tasks with high precision, ensuring consistent product quality. To explore how turnkey solutions contribute to consistent quality, check out this link.

Artificial Intelligence and Machine Learning

AI and machine learning are increasingly being integrated into manufacturing processes to predict maintenance needs, optimize production schedules, and improve supply chain management. These technologies provide manufacturers with valuable insights that enhance efficiency and reduce operational costs.

The Role of Exporters and Importers

Exporters and importers are vital to the electronics manufacturing industry, especially in the context of medical devices. They ensure that products reach global markets, facilitating international trade and collaboration.

Challenges Faced by Exporters and Importers

The global nature of the electronics industry means that exporters and importers must navigate complex logistics, tariffs, and trade regulations. Understanding these challenges is crucial for success in this field.

Opportunities for Growth

Despite the challenges, there are significant opportunities for growth in the electronics manufacturing industry. With the increasing demand for medical devices, exporters and importers can capitalize on expanding markets and technological advancements.

Future Trends in Electronics Manufacturing for Medical Devices

Looking ahead, the future of electronics manufacturing for medical devices is bright, with several trends set to shape the industry.

Personalization and Customization

There is a growing trend towards personalized and customized medical devices. Advances in manufacturing technology, such as 3D printing, allow for the production of tailor-made devices that meet specific patient needs.

Sustainability and Eco-friendliness

Sustainability is becoming increasingly important in manufacturing. Companies are adopting eco-friendly practices and materials to reduce their environmental impact, which is not only beneficial for the planet but also appealing to consumers.

FAQs

What are the key challenges in electronics manufacturing for medical devices?

Key challenges include maintaining high quality, adhering to regulatory standards, and managing complex global supply chains.

How does technology enhance the production of medical devices?

Technology enhances production by improving efficiency, reducing errors, and allowing for the creation of more sophisticated and reliable devices.

Why is regulatory compliance important in this industry?

Regulatory compliance ensures the safety and efficacy of medical devices, allowing them to be used confidently by healthcare professionals and patients.

For further reading on choosing the right manufacturing approach, check out this guide.