The world of automotive electronics is ever-expanding, with new technologies making vehicles smarter, safer, and more efficient. At the heart of this evolution is turnkey manufacturing for automotive electronics, a process that ensures the seamless production of electronic components used in vehicles. This method is gaining traction among exporters and importers for its ability to streamline production while maintaining quality.

What is Turnkey Manufacturing?

Turnkey manufacturing refers to a comprehensive solution where a single provider handles every aspect of the manufacturing process. From design and prototyping to production and testing, everything is managed under one roof. This approach eliminates the need for multiple suppliers, reducing complexity and enhancing efficiency.

The Role of Turnkey Manufacturing in Automotive Electronics

In the realm of automotive electronics, turnkey manufacturing plays a crucial role. It enables the production of complex electronic systems that are integral to modern vehicles, including infotainment systems, advanced driver-assistance systems (ADAS), and more. By adopting a turnkey approach, manufacturers can ensure these components meet stringent automotive standards.

Benefits of Turnkey Manufacturing for Exporters and Importers

For exporters and importers, turnkey manufacturing offers numerous advantages. It simplifies the supply chain by consolidating multiple processes, thereby reducing lead times and costs. Additionally, it provides a single point of contact, making communication more efficient.

Key Steps in Turnkey Manufacturing Process

1. Design and Prototyping

The journey begins with design and prototyping. Engineers work closely with clients to develop detailed designs and prototypes, ensuring that the final product aligns with the client’s specifications and industry standards.

2. Component Sourcing

Once the design is finalized, the next step is sourcing components. Turnkey manufacturers have established relationships with reliable suppliers, ensuring access to high-quality materials at competitive prices.

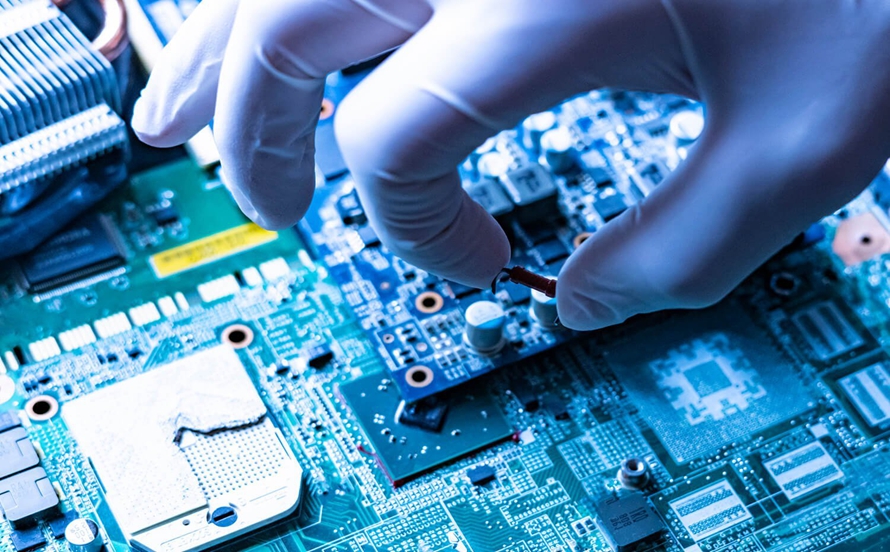

3. Assembly and Testing

The assembly process is carried out in state-of-the-art facilities equipped with advanced machinery. Rigorous testing is conducted at every stage to ensure the components meet the highest quality standards.

Challenges in Turnkey Manufacturing

While turnkey manufacturing offers numerous benefits, it is not without its challenges. Manufacturers must navigate complex regulatory requirements and stay abreast of technological advancements to remain competitive. Additionally, managing supply chain disruptions and maintaining quality control can be daunting tasks.

Quality Assurance in Turnkey Manufacturing

Quality assurance is paramount in turnkey manufacturing. Manufacturers implement stringent quality control measures to ensure that each component meets the required specifications. This includes regular inspections and testing, as well as adhering to international standards such as ISO 9001.

Future of Turnkey Manufacturing in Automotive Electronics

The future of turnkey manufacturing in automotive electronics looks promising. As the demand for advanced electronic systems in vehicles continues to grow, the need for efficient and reliable manufacturing solutions will increase. Turnkey manufacturing is well-positioned to meet this demand, providing a seamless and cost-effective solution for producing high-quality electronic components.

Technological Advancements

Technological advancements are driving the evolution of turnkey manufacturing. Automation, artificial intelligence, and the Internet of Things (IoT) are being integrated into manufacturing processes, enhancing efficiency and precision.

Conclusion

In conclusion, turnkey manufacturing for automotive electronics is a game-changer for the industry. It offers a streamlined approach to production, ensuring high-quality components are delivered on time and within budget. For exporters and importers, embracing this method can lead to significant advantages in terms of cost, efficiency, and product quality.

Frequently Asked Questions

1. What are the main benefits of turnkey manufacturing?

Turnkey manufacturing offers several benefits, including reduced complexity, cost savings, improved quality control, and faster time to market.

2. How does turnkey manufacturing ensure quality?

Quality is ensured through stringent quality control measures, regular inspections, and adherence to international standards.

3. What is the future of turnkey manufacturing in the automotive industry?

The future looks bright, with advancements in technology driving the evolution of turnkey manufacturing, making it more efficient and precise.

For more information, you can visit this comprehensive guide on turnkey PCB manufacturing.